We’ve been quietly testing the cloud-based 3DPrinterOS recently and asked the company to tell us the latest developments.

If you’re not familiar with 3DPrinterOS, it’s a cloud-based service that connects to your 3D printer, typically by direct USB attachment from a computer or Raspberry Pi. Your interaction with the 3D printer then occurs from a web page, where you can load models, slice them and ultimately direct them to the 3D printer. The cloud service performs all the work, including dribbling GCODE at the printer during print operations. You’ll even be able to monitor and control the 3D print from a web page.

Here’s the best part: since you access the 3D printer from 3DPrinterOS’s web page, this means you can access and control your 3D printer from literally anywhere. Even from a mobile phone. If you’re printing and happen to have a camera-equipped device, you can even see the print proceed – and stop it if something went wrong.

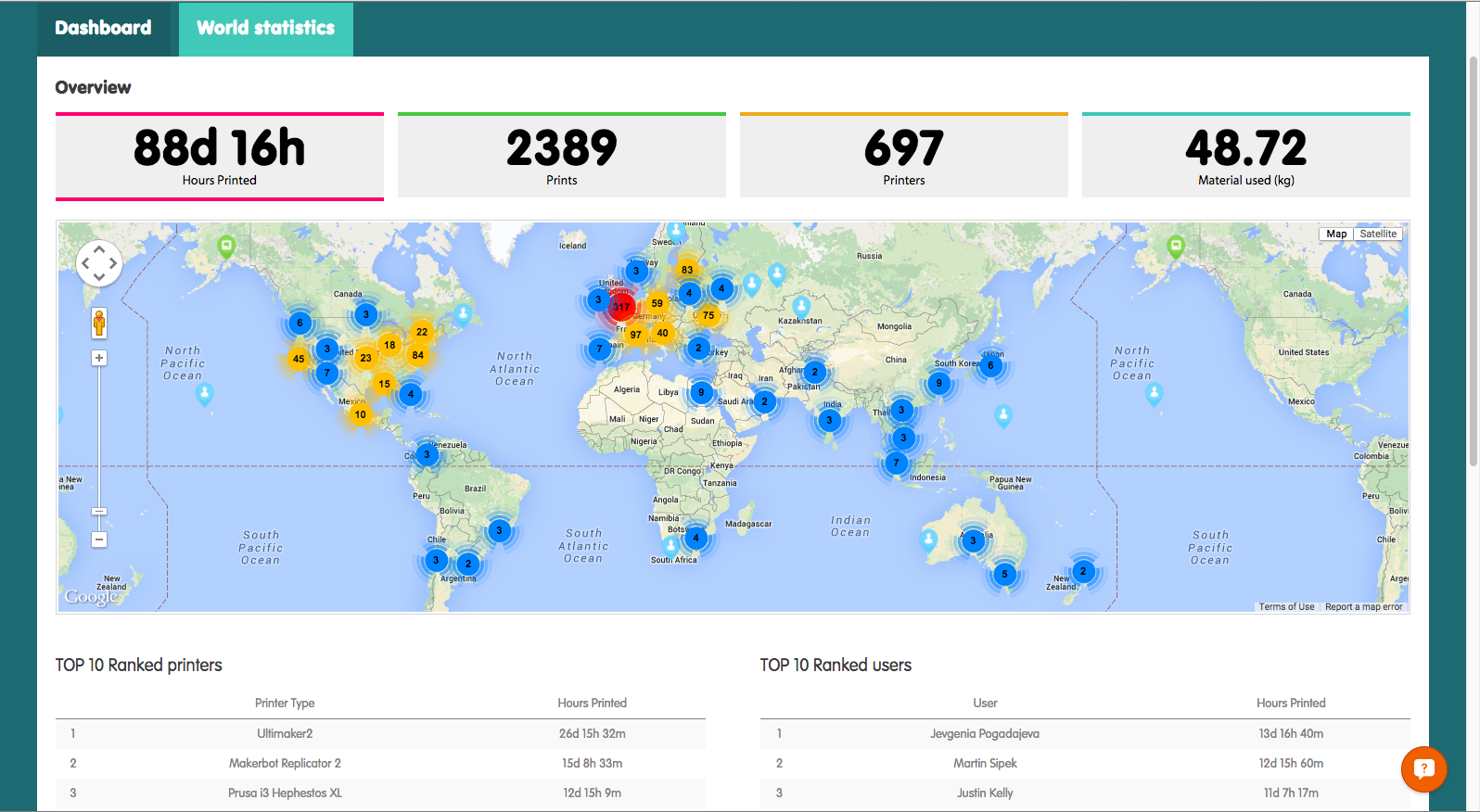

The company opened up access to the network to the public on March 18th and since then we’re told they’ve had well over 1,000 new users from 59 countries subscribe – which, we should say, is entirely free of charge. So far these users have generated over 2,000 hours of 3D printing.

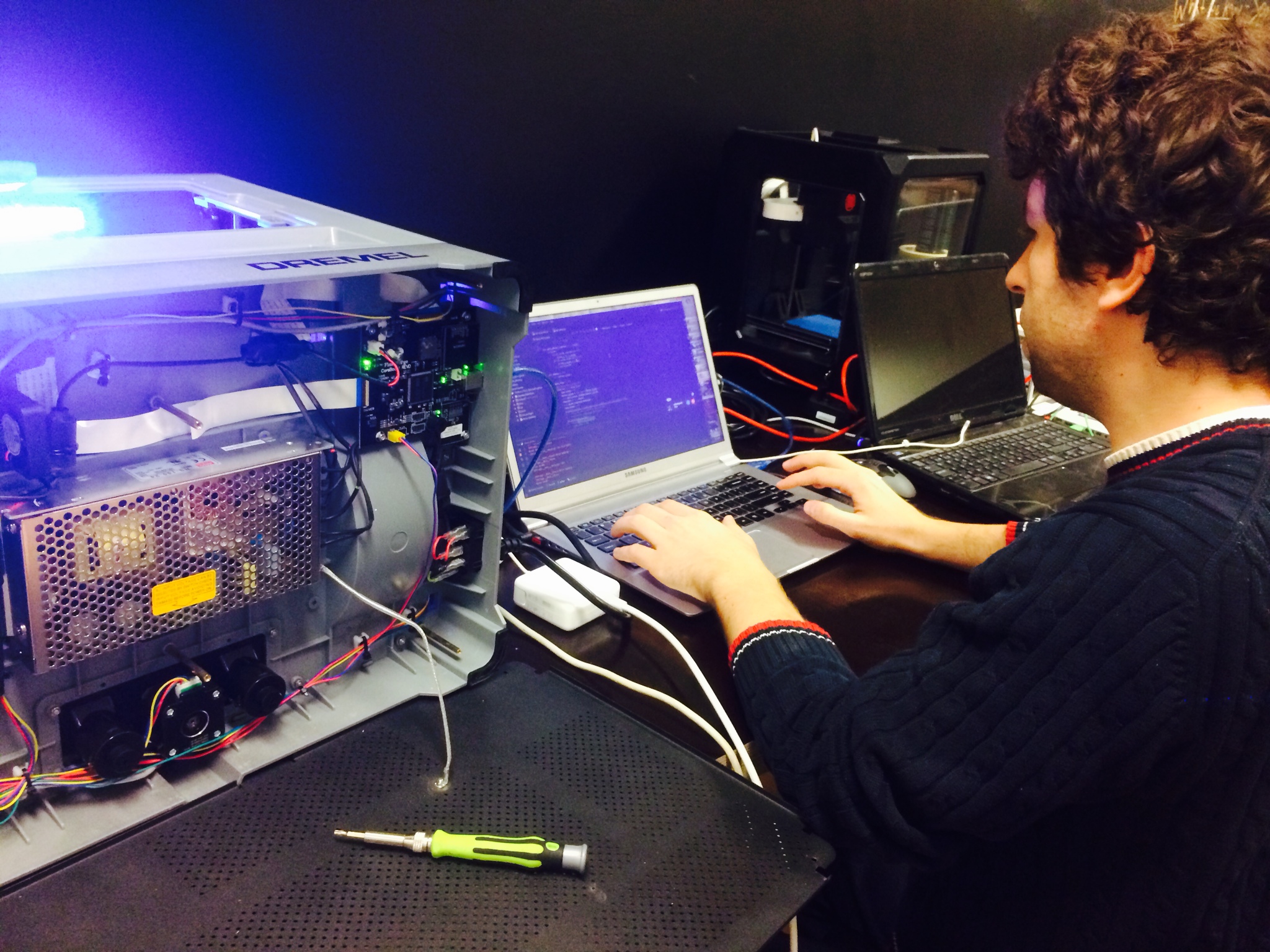

We asked 3DPrinterOS’s Aaron Roy (he’s on the right with Charles Driza, also from 3DPrinterOS) about the most challenging puzzles they’ve encountered in building this service:

Multi-Printer Support from a Single Device

Aaron Roy: Understanding how to do multi-printer support from a single device (i.e. 1 Raspberry Pi 2 and two different 3D Printers connected) and making the software intuitive enough to work with printer serial numbers thus making it plug and play instead of our old “keyed method” of connecting printers to the cloud took quite a bit of development time. Figuring that out has allowed many of our users to add and manage multiple printers with ease. This is incredibly important for schools who may have 6 printers and one admin. Right now you could also plug in 2 printers from 2 different manufacturers and be able to control both as well. This was very difficult for past 3D software.

3D model Viewing and Editing

Aaron Roy: Before we had no way to move prints from the center of the print bed and this was tied into implementing a new 3D Library on our site. We developed and released a new STL editor for our system. Our new STL editor allows moving, resizing, rotating and positioning on any of the printer beds we support. We will add cloning and multi object support shortly. The challenge was finding a 3D Library that could handle files from 1MB to 100MBs with ease while rendering in the cloud. We’re excited by this new release because now we can improve our other apps in our platform to load and process even faster moving forward.

Cloud Slicing

Aaron Roy: As we developed this system and had beta testers trying our slicer we realized our old infrastructure could never scale and keep slicing incredibly fast, thus we switched to Amazon’s cloud and rebuilt our entire infrastructure to make sure we could infinitely scale moving forward.

Making Models Printable

Aaron Roy: We realized that many files from Thingiverse and YouMagine are simply not ready for 3D printing right away. They might need clean up, repair, or orientation for a specific printer before being able to print. We had to develop our “Magic Fix” app in response because for one click manufacturing to be a reality in the future you need the ability to run all of those processes with ease and quickly. This has allowed us to work with schools and newer generations of makers as some of the barriers of success for making that first print are now removed!

Our testing of this interesting service continues. We’ll be writing up a more detailed post on our findings very soon.

Via 3DPrinterOS