A new venture is purchasing scrap plastic for eventual use in 3D printers.

Plasticbank, based in Vancouver, operates a recycling service for scrap plastic in the lower British Columbia mainland. Here’s how it works: local folks are paid for scrap they collect. Plasticbank feeds the scraps into their equipment, which reduces the scrap into usable plastic pellets. These pellets can be sold to manufacturers for use in various plastic products.

While the resulting plastic is somewhat more expensive than “fresh” plastic, companies are willing to use the material in their products to support the notion of recycling.

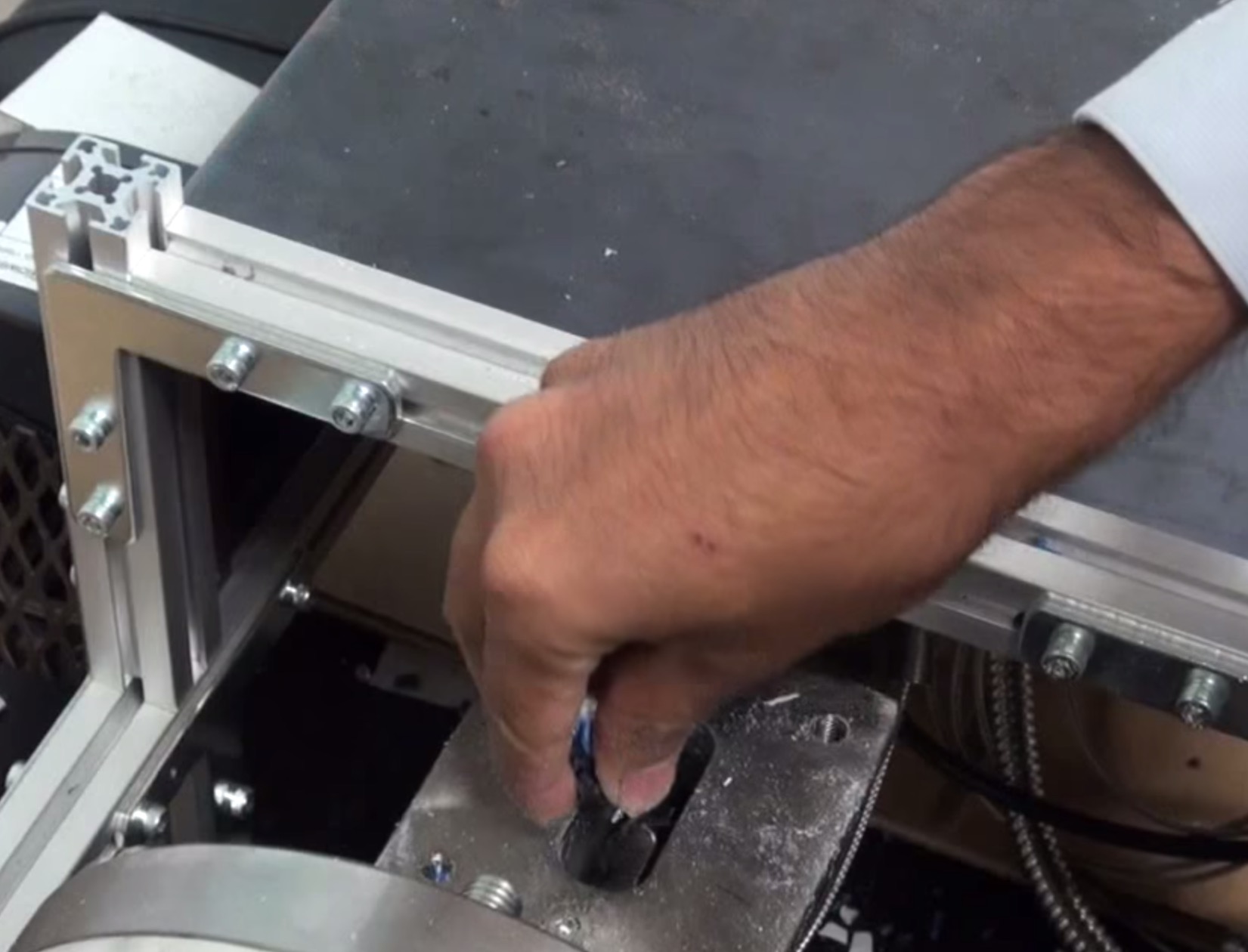

Another use, according to Plasticbank, is as 3D printing filament. They propose feeding the pellets into filament-making machines to extruder spools of fresh filament. They’ve even released an open source recycling machine’s design, the Recyclebot.

While this program is obviously good for the community, it has a couple of very serious challenges when it comes to 3D printing.

The first major challenge is material consistency. Scrap plastic, by definition, is going to arrive in many flavors. It will be different kinds of plastic (HDPE, ABS, Nylon, perhaps even PLA). Each of these substances has different extrusion characteristics – like extrusion temperature, viscosity, adherence, etc. Unless these plastics are somehow identified and carefully separated, a dog’s breakfast of materials will be unusable for 3D printing. Even when separated into basic materials, there is no way to ensure the consistency of each material: there are different polymer mixes everywhere and it’s highly unlikely a beach would be covered in only one composition. And don’t even mention colors.

The second major challenge is material quality. We’ve inspected large filament factories that have spent considerable time and money to develop production lines capable of producing high quality filament – and it is definitely not easy. While it is easy to make a machine that extrudes filament, there is simply no way such a device could approach the quality of a factory. The filament will be of inconsistent diameter and shape, could have moisture infiltration, particle contamination and more. These problems cannot be solved with a desktop machine. Worse, as personal 3D printers increase in capability, the need for high quality filament will become critical and solutions such as proposed by Plasticbank will have a more difficult time finding a market.

Today the best approach for recycling 3D printer plastic is likely using PLA plastic, which is a biodegradable organic substance itself.

Via Plasticbank