In the past year there have been many attempts to develop a reliable way for prints to stick to the print surface. Some are rigid, and some are flexible.

Traditionally, sticking was accomplished with heated beds that prevent plastic from slowly warping off the print surface, or various sticky solutions such as tape, hair spray or even an application of the target plastic itself. These work, but are often messy and may require post-print effort to cool, pry or wash off the completed prints.

Alternative solutions appeared, with replacement build plates or special surfaces that can be glued or attached to existing build plates that provide “automatic” sticking by chemistry.

We believe the flexible solutions are better.

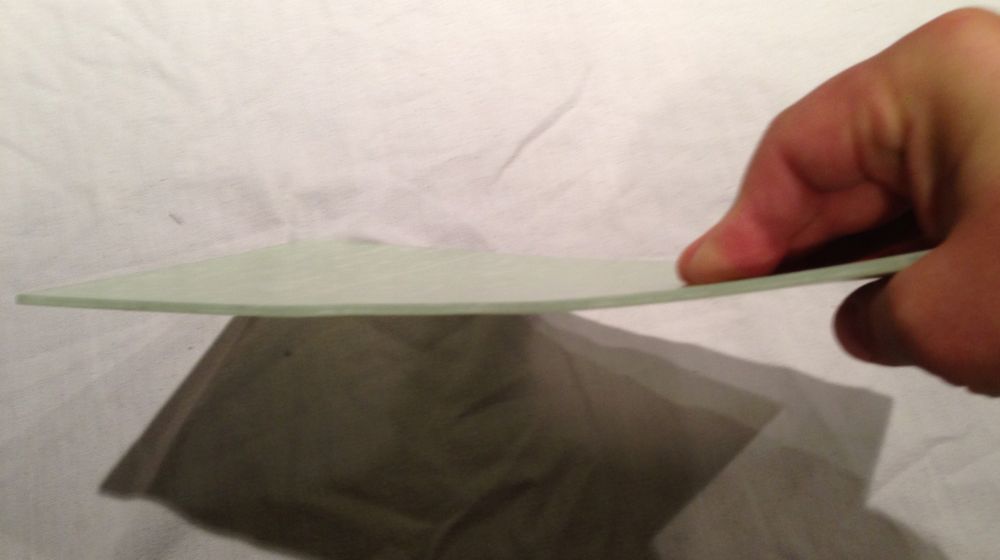

Why? It’s because removal of printed items from the plate is just easier. A removable “sticking plate” can be temporarily bent, causing the prints to immediately “pop off” without much effort – and almost instantly. In this image you can see how it can work; it’s very similar to popping ice cubes out of a freezer tray.

Heated print plates offer good sticking ability too, but removal is sometimes accomplished by waiting for the bed to sufficiently cool and release the plastic prints.

Rigid solutions often require challenging print removal operations involving sharp lifting tools and a lot of grunting. In some cases, as we can see in the image at top from Reddit user Impaktful, sticking too well can actually harm your device’s print surface – in Impaktful’s case, catastrophically: the plate broke during part removal. While Impaktful’s problem occurred using blue tape, the same could happen with any fancy sticking solution that’s permanently glued to the print surface.

It’s much easier to casually remove a special print surface and bend it. This is also a lot safer for your printer, too, as no dangerous tools need be applied to the original print bed or within the printer itself.

Our favorite flexible print surface at the moment is PRINTinZ’s build plates, which can be quickly clipped onto an original print surface (even a heated one) and unclipped for removal of finished prints.