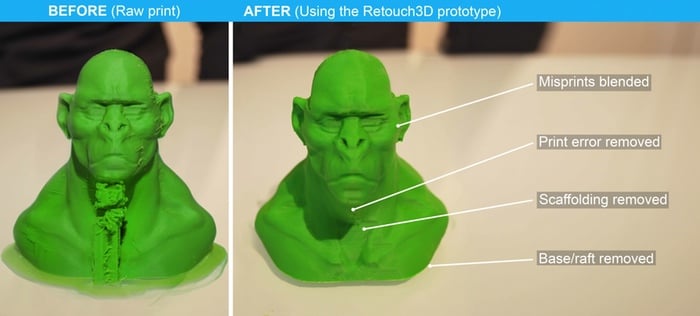

A new product has launched that could make finishing 3D prints a great deal easier.

It’s called the “ReTouch3D” and is essentially a handheld heat applicator with interchangeable heads. The idea is to selectively melt and reform small poorly printed areas on a print’s surface. They explain:

Forget snapping, scraping, and sanding; Retouch3D’s variable heat control system and interchangeable heads mean you finish-off all your 3D prints like a pro.

Retouch3D’s ergonomic handheld design combines comfort and precision, allowing makers to clean-up 3D prints with the assistance of heat which is matched to the melting properties of their printing material.

Some 3D printer operators use the acetone vapor method of smoothing prints, which also repairs some small defects, but this is quite a different – and perhaps simpler – approach. It works on PLA and Resin prints as well as ABS, too.

Once a print completes, there’s often more work to do:

- Picking off support structures

- Removing stubs from said support structures

- Removing stray plastic strands that someone appeared during printing

- Removing excess blobs

The ReTouch3D’s heated end can do all of this and more. In fact, one of the maddening occurrences when examining a print is small gaps caused by questionable filament or extruder hiccups. These cannot be “fixed” by snipping off additional material, as you might with other print problems. With the ReTouch3D you can fill the gaps by melting nearby material and smoothing it over the hole.

How does it work? Simply select the appropriate end tool for the job from the available set of five, pick the right heat setting for the plastic and go to it. It’s much like using a soldering iron, but with a tool designed specifically for this purpose.

Why not just use a soldering iron? They explain:

After experimenting with various off-the-shelf heated tools we soon learnt that to successfully create Retouch3D there were a number of different factors that came into play when building a complete solution.

Their ergonomic handheld device is safe to leave on a table (the hot tip won’t touch the table), and offers the ability to fine-tune the heat setting for the particular job at hand.

As has become customary, the ReTouch3D is offered in a variety of packages on their Kickstarter page. But the thing to know is that the earlier you buy one, the less expensive it will be. The initial batch is priced at USD$149 per unit, rising to USD$179 and finally USD$199. Get one and get one early!

Via Kickstarter