If you are anywhere close to the world of 3D printing, you no doubt saw the blockbuster announcement last week of Carbon3D’s new speedy process. We took a bit deeper look at it.

Specifically, we reviewed a scientific paper on the process, “CLIP” (continuous liquid interface production), authored by several Carbon3D scientists as well as individuals from the University of North Carolina and North Carolina State University.

Entitled, “Continuous liquid interface production of 3D objects”, the paper explains the science behind the process touted as being able to 3D print items up to 100x faster than conventional 3D printers. Their abstract:

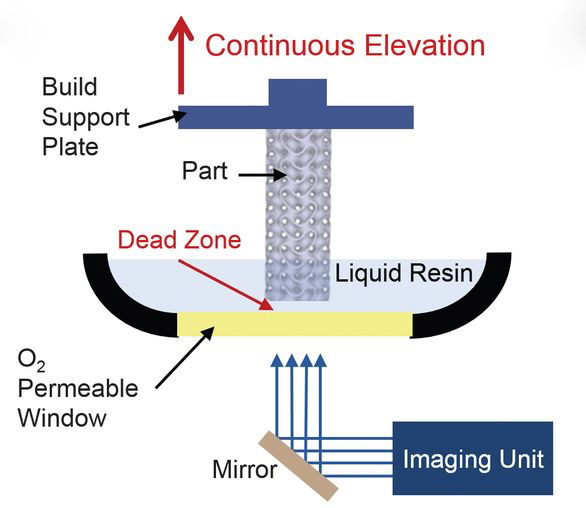

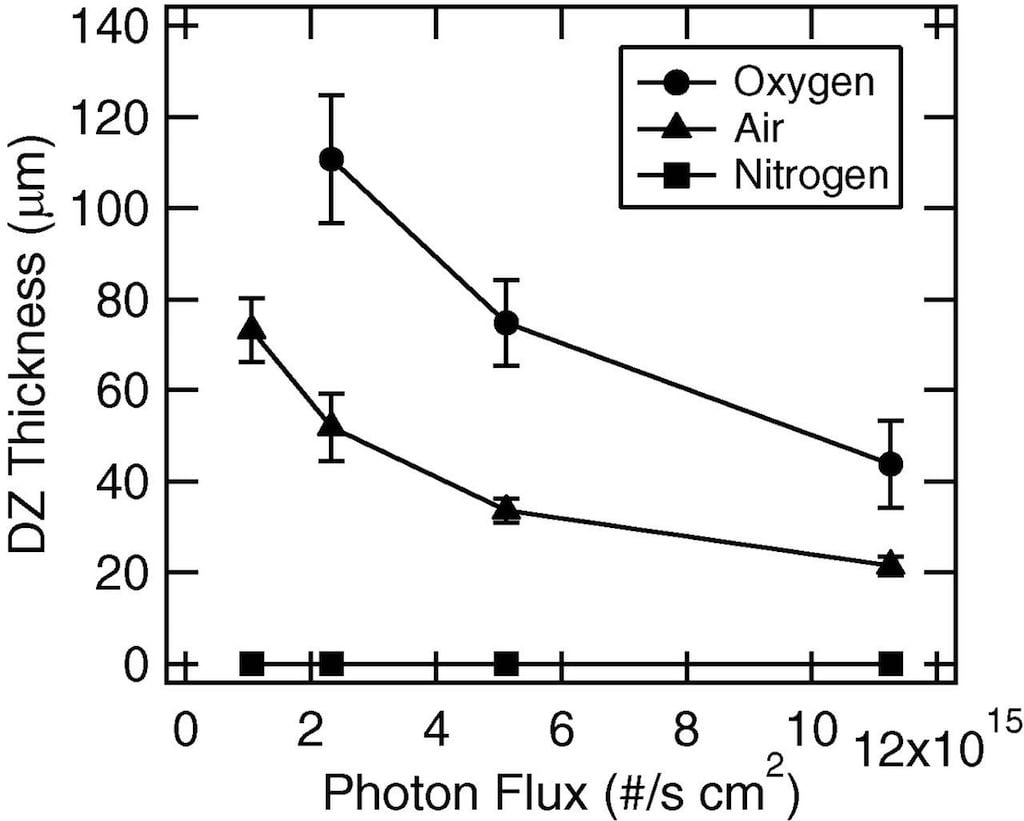

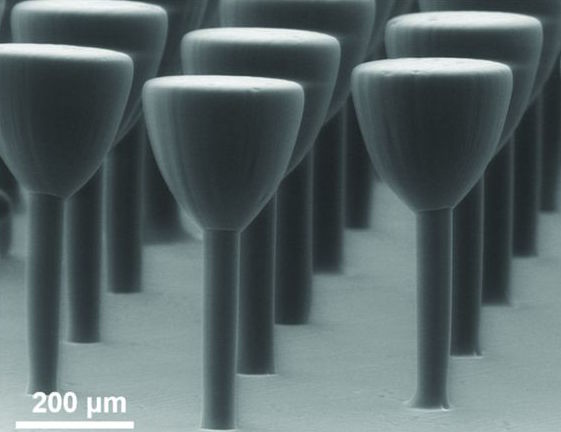

Additive manufacturing processes such as 3D printing use time-consuming, stepwise layer-by-layer approaches to object fabrication. We demonstrate the continuous generation of monolithic polymeric parts up to tens of centimeters in size with feature resolution below 100 micrometers. Continuous liquid interface production is achieved with an oxygen-permeable window below the ultraviolet image projection plane, which creates a “dead zone” (persistent liquid interface) where photo polymerization is inhibited between the window and the polymerizing part. We delineate critical control parameters and show that complex solid parts can be drawn out of the resin at rates of hundreds of millimeters per hour. These print speeds allow parts to be produced in minutes instead of hours.

The paper explains the chemistry behind the creation of a so-called “dead zone”, at the bottom of a resin tank. The dead zone occurs because the presence of sufficient oxygen inhibits photocuring the resin. They’ve been able to create and maintain a dead zone only “tens of micrometers” thick. This dead zone permits continuous UV-curing because there is no delay required to re-flood the build area with fresh resin; resin is always available because there’s no contact between the solidified object and the bottom of the tank.

Therefore, the speed of printing is limited only by the speed at which UV light can solidify the resin. Other approaches require not only curing time, but also re-flood time to bring more resin into the build area.

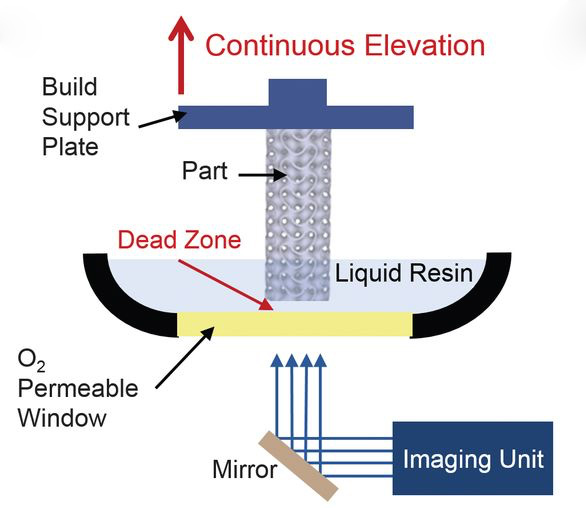

Evidently this team has performed very significant research to develop the dead zone technology, as they’ve had to consider various factors that could affect the oxygen permeability, including photon flux, nitrogen presence and clear materials from which the tank is made.

They’ve identified a trade-off between the thickness of the dead zone, printed layer size and print speed. This means 3D printers eventually built to use CLIP technology will incur the same trade offs.

They say that for a 20 micron dead zone, they can print 100 micron layers vertically over 300mm per hour (almost 12 inches per hour!) However, if you sacrifice resolution and print 300mm layers, a typical print resolution for common 3D printers, the speed increases to 1000mm per hour.

That’s incredible! Imagine printing a typical 100mm object that today would take perhaps an hour on a standard filament machine could take as little as six minutes! Even better, the CLIP process is less sensitive to the X-Y size of an object as compared to filament extrusion approaches.

With the large funding obtained by Carbon3D, it’s likely they could become a very major player in the 3D printing market. Meanwhile, this development should be concerning to some of the existing major players and especially to smaller manufacturers of resin-based gear.

Via ScienceMag (Free registration required) (Hat Tip to Tom)