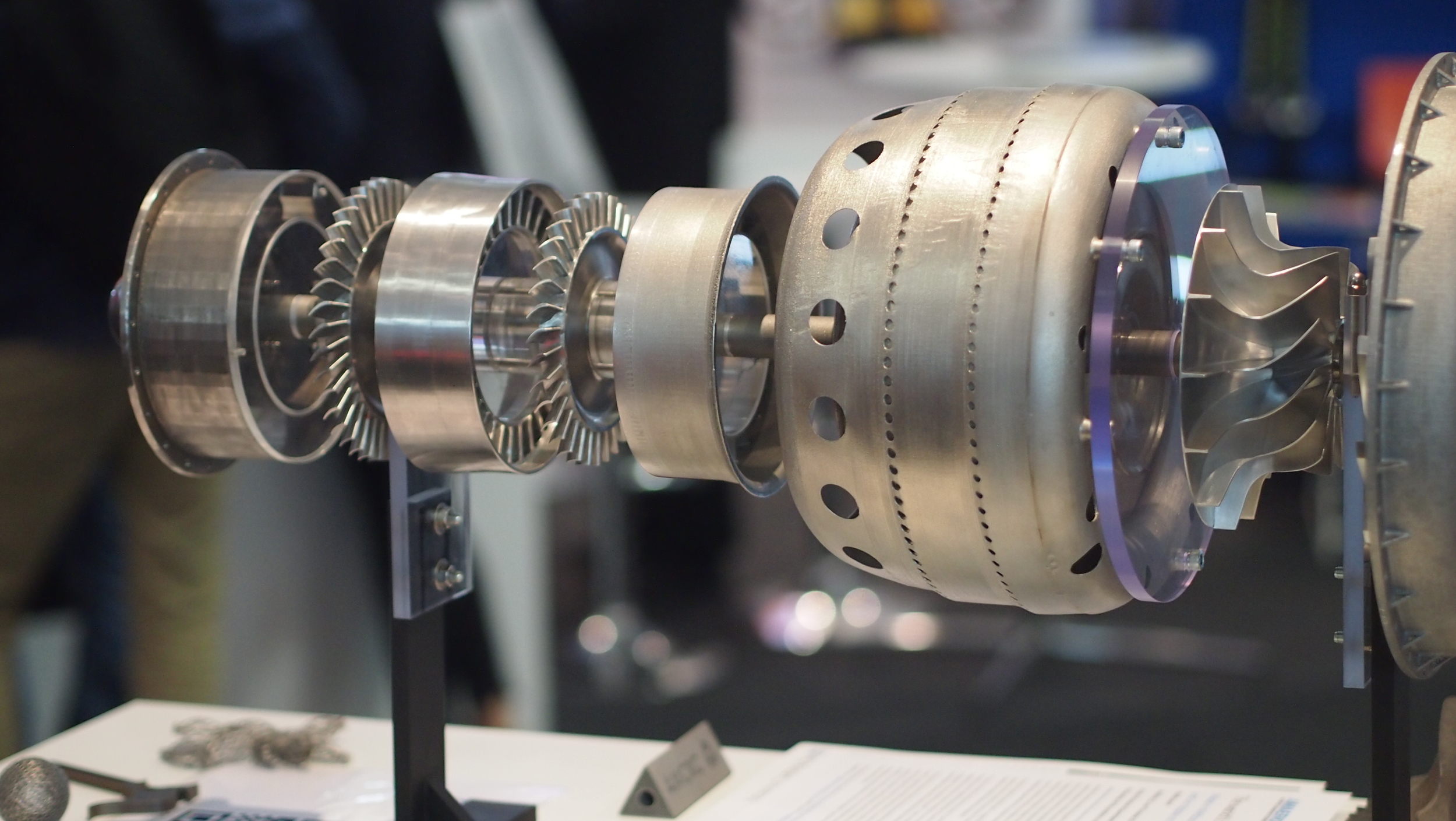

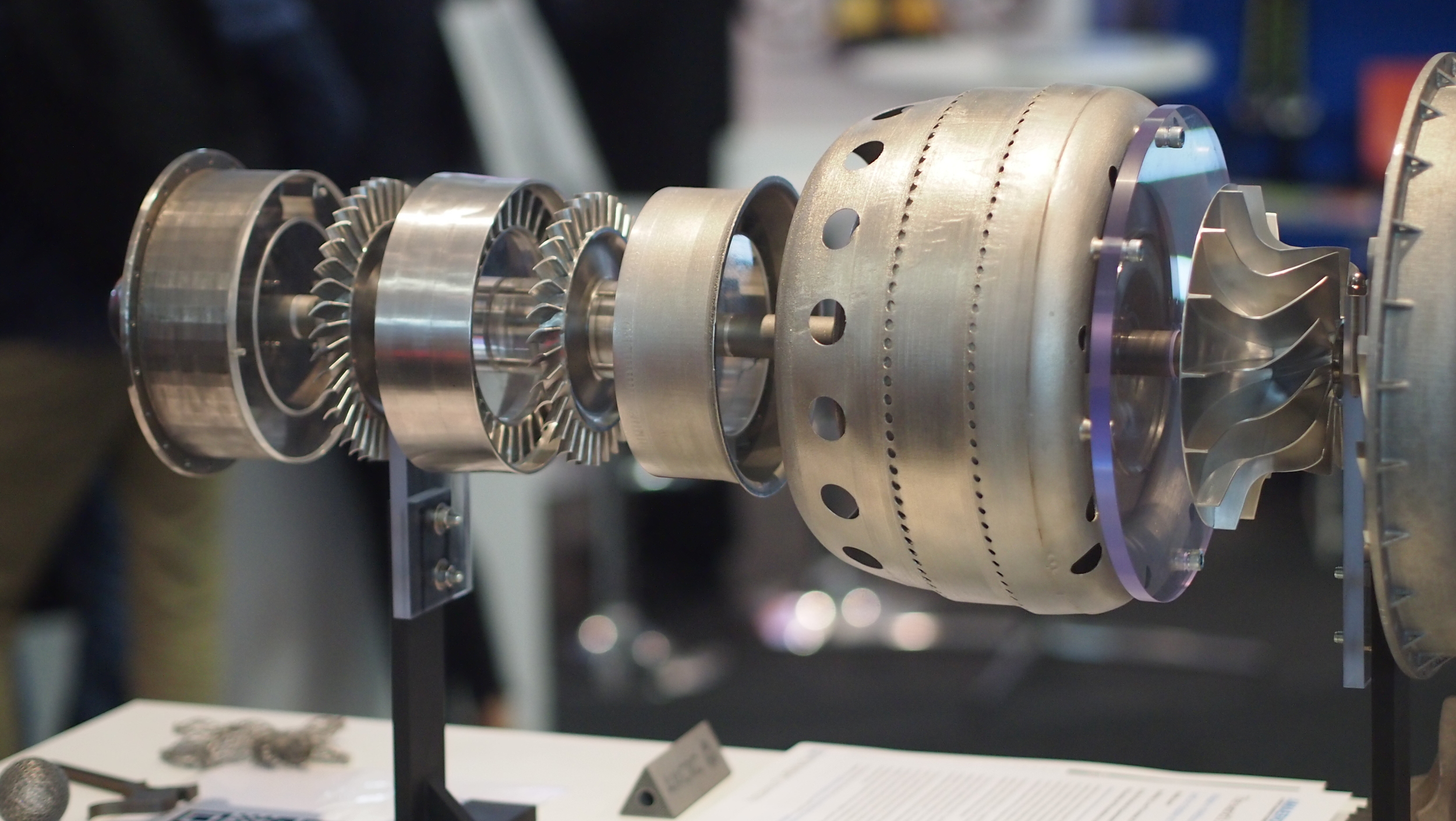

A team of 3D print researchers has managed to 3D print an entire jet engine.

The group, from Melbourne Australia-based Monash University, have actually printed two complete jet engines using metal 3D printing technology.

The process, which took some two years to complete, involved obtaining permission to 3D scan the internal components of an existing turbofan auxiliary power unit used in smaller aircraft. Each scanned part was then printed in solid metal using the EOS and Concept Laser gear at the Monash Centre for Additive Manufacturing in Melbourne.

While these parts have been printed and assembled into a jet engine, it is not known whether the engine has been fired. This is also a key test, as the mechanical rigors of engine operation will provide a test for the strength of the 3D printed parts.

This is only a first step, a kind of demonstration. If the parts prove sufficiently strong to make up a working and durable 3D printed jet engine, then researchers can move on to leveraging 3D print technology to develop parts in new ways. In this experiment, the advantages of 3D printing, namely the ability to print any geometric shape, were not used, as the demonstration involved scanning an existing design.

Future experiments could result in engines with far fewer parts, lighter weight, improved safety, smaller occupied volumes or even unusual performance characteristics. There’s a lot more to do after this first test.