We’ve previously written about 3DP Unlimited’s massive 3DP1000 3D printer, but today we’re looking at the prints it produces.

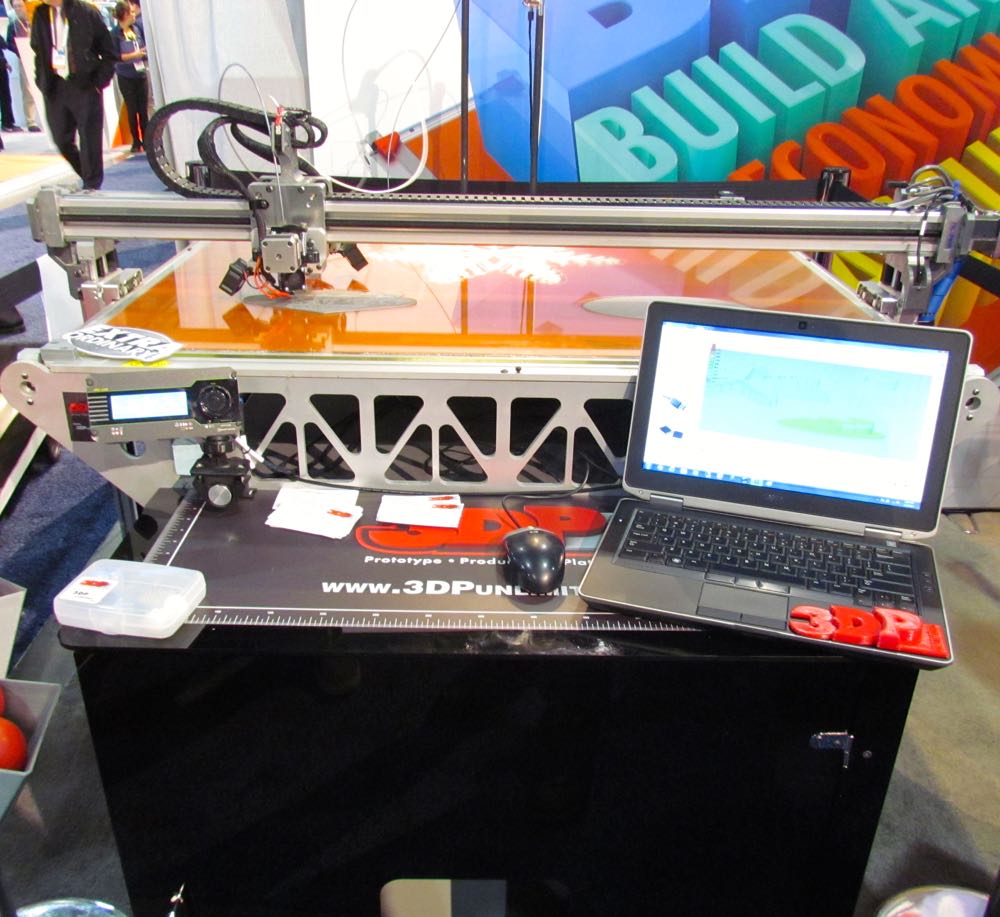

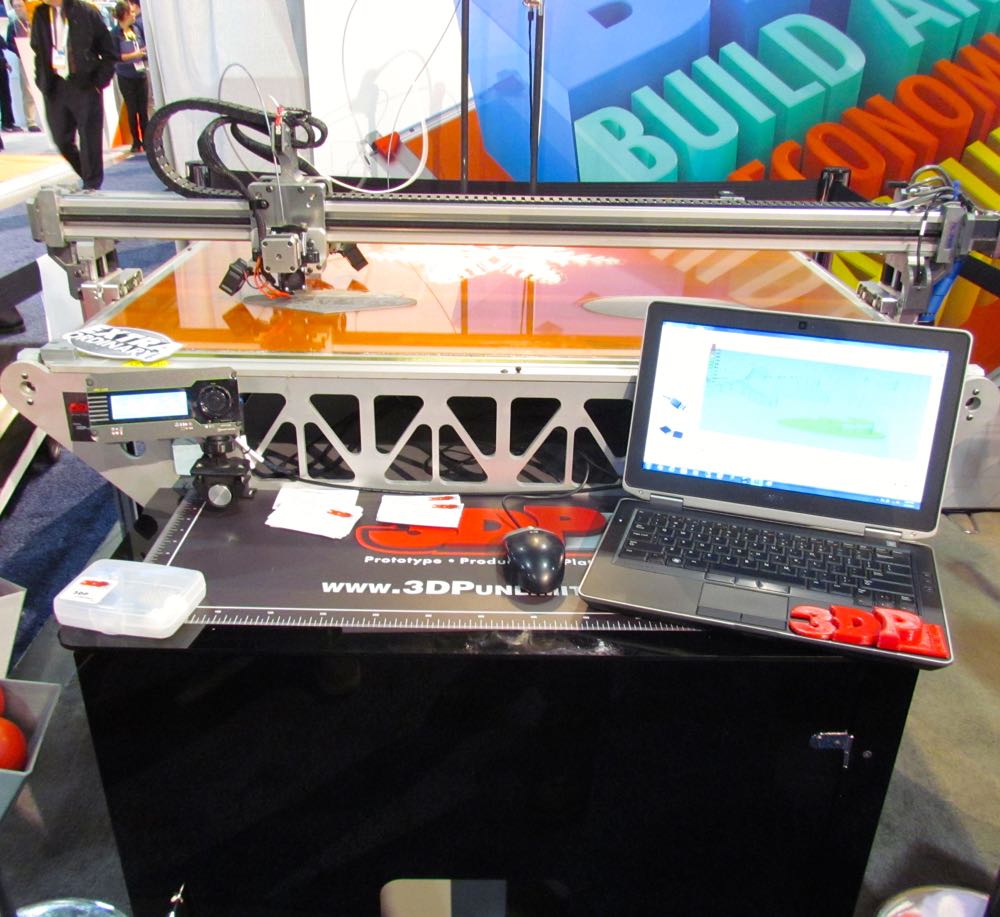

The machine, if you’re not familiar, is a 3D printer using the familiar filament extrusion process. The most notable aspect is the size of the print: 1000 x 1000 x 500mm. That’s correct – you can print items 1m wide. Even wider if you print them on the diagonal.

The 3DP1000 is capable of printing in a variety of filament materials, as it includes a heated borosilicate glass print surface. It’s a large unit, as you can see in the image at top.

But what about prints? Here we have a chair printed on the 3DP1000. This item took 225 hours to print and used 13Kg of 3mm PLA. We’re not sure if it’s strong enough to sit on, but it was printed in one piece.

This item is a prototype of an engine block, printed life size. This must be one of the largest single prints we’ve yet seen. The engine block required 22.5kg of PLA and an astonishing 406 hours of continuous printing. That’s 16 DAYS and 22 hours.

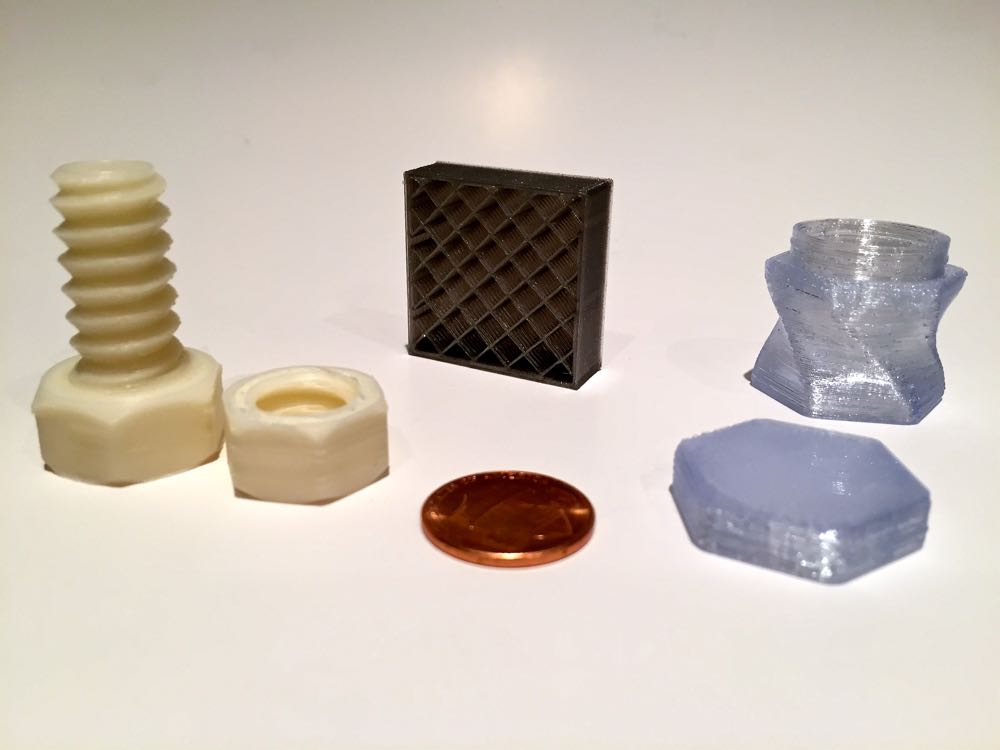

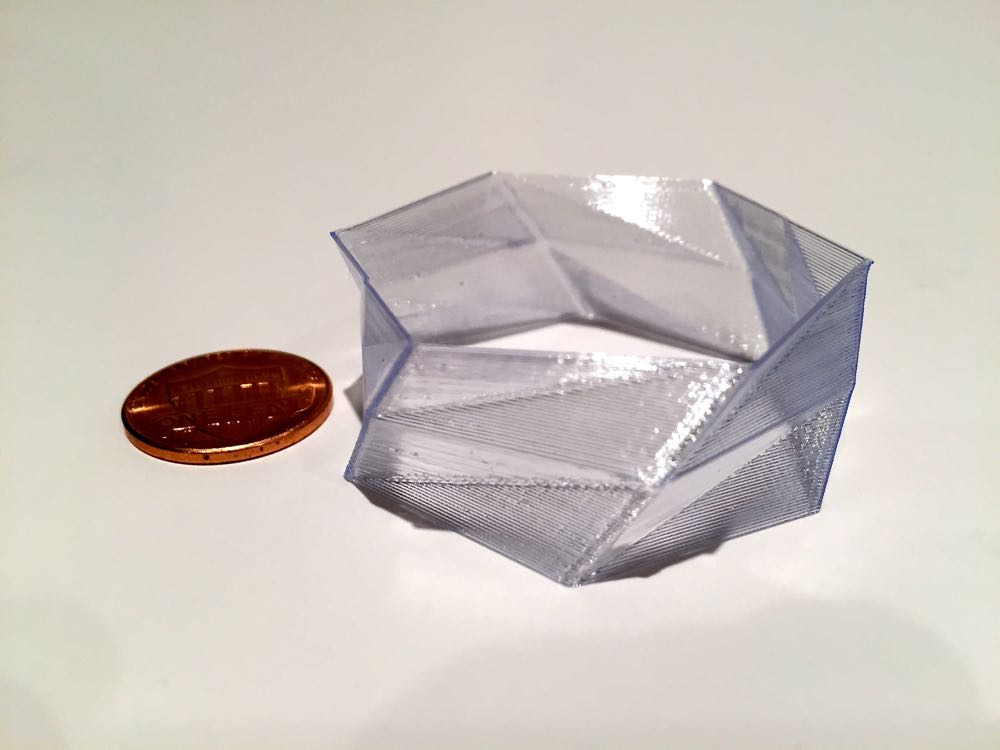

Surprisingly, the 3DP1000 also performs very well when printing very small items. Here we see a selection of threaded items printed on the device. Each part is dimensionally accurate, with nut and bolt fitting easily together.

This example shows very fine detail, which is quite amazing for a machine of this size.

Of course, printing at a very fine resolution (and the 3DP1000 can print layers as small as 0.07mm) can very significantly add to the print time, particularly on very large objects such as those above. However, for larger objects high resolution is often unnecessary.

We suspect that part of the reason this machine works so well is the underlying hardware. 3DP Unlimited is actually a branch of PBC Linear, makers of very precise linear motion platforms. In other words, if you’re building a 3D printer that provides precision control at a large scale, you’d best use premium components.

Via 3DP Unlimited