Does the quality of 3D printers vary among machines? Yes. Is it possible to hide flaws? Also, yes.

We’re talking about inspecting sample printed objects. As anyone who’s used a personal 3D printer knows, some geometries are more difficult to print than others. Some objects are very “easy” to print, in that they don’t stress the printer’s capabilities.

What exactly are we referring to? Generally, 3D printers seem to have a easier time printing continuously and get into trouble when they stop and start within layers.

Consider the example shown at top, a beautiful vase by Virtox, printed by almost everyone. One reason everyone prints it is because it almost always comes out perfectly. And that’s because the extruder, once it starts on a layer, simply continues looping through each layer. There’s no stopping and starting, no sharp movements for the extruder to endure. It’s a smooth ride, from start to finish; A great design for 3D printing.

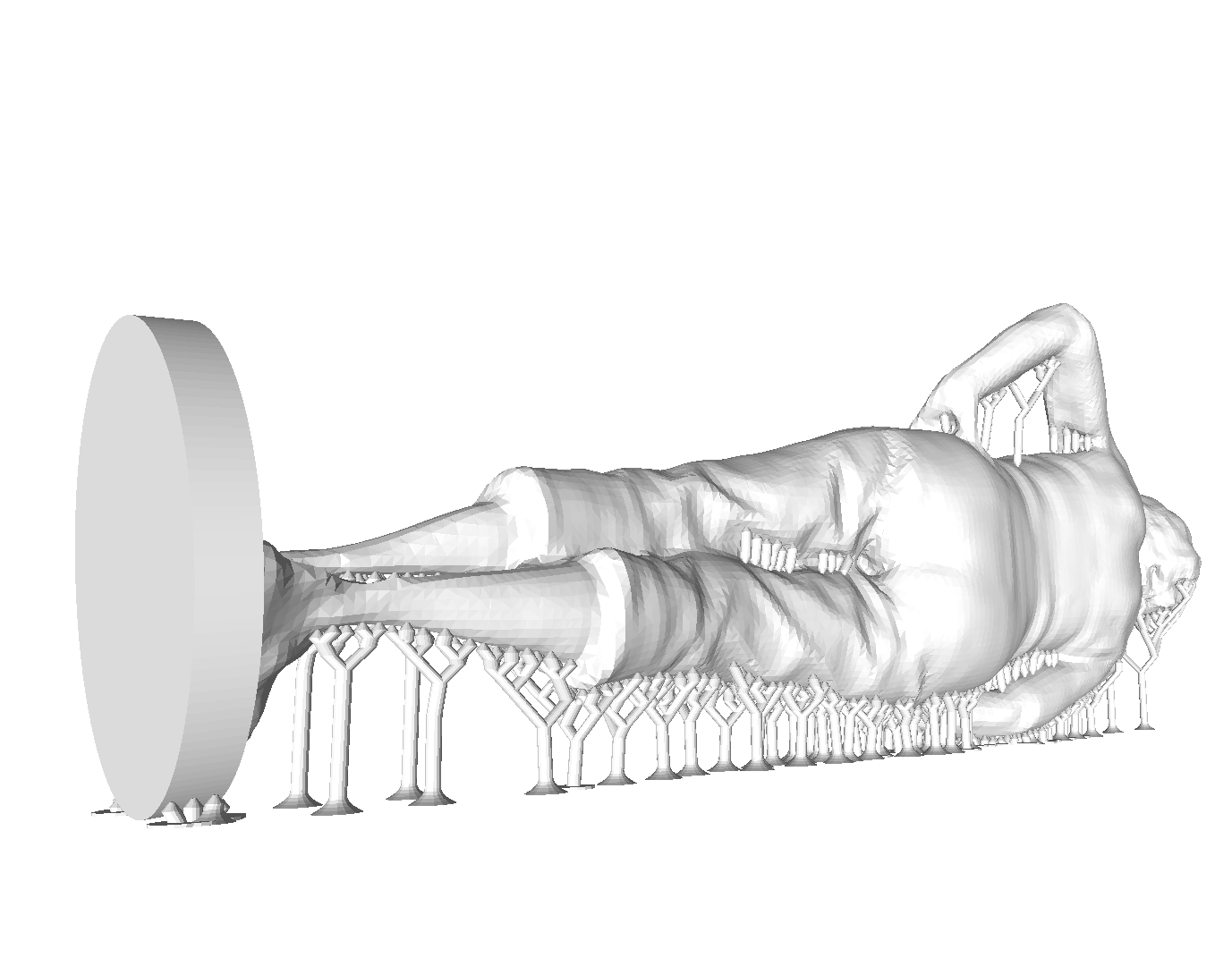

Meanwhile, people often want to print more complex items. Consider this item, a figurine laid on its side to obtain more print length. There are innumerable support structures to print, causing the extruder to sharply move from point to point, extruding very small amounts that must somehow pile up in tall straight columns.

Consider this unlikely pair of prints from the same machine and same spool of filament – and identical printing parameters. On the left, the horrifyingly bad 3D print of a small figurine demonstrates issues moving between the torso and arms. In fact, the print was so catastrophically bad a leg was lost in the process (and almost an arm, too, for that matter). Meanwhile, the curvy head on the right came out near-perfect. But, as you can see from the design, it’s like a vase: a nearly continuous extrude, from start to finish.

Bottom line: when inspecting print samples from any machine, either in your hands or from images, check out the nature of the 3D model. If it’s an easy print, ask to see something more complex printed before you commit to a purchase.