A startup company has developed a way to produce high quality recycled 3D printer filament.

Dimension Polymer’s Kickstarter campaign officially launches their new product, spools of filament made from recycled ABS plastic, is available for USD$30 per 750g in either 1.75mm or 3.00mm formats.

This is not the first attempt at recycling plastic for 3D printer use. We’ve seen multiple attempts at this, sometimes with a devices that grind up old prints into pellets that are heated and extruded into fresh filament – or third world ventures involving recycling of scrap plastic.

Both of these approaches have difficulties in two areas.

First, the filament quality is usually inadequate for precision use in 3D printers. The diameter of the filament may vary more than tolerances should allow, as inexpensive filament-making gear just can’t compete against industrial grade filament production lines.

Recycled filament quality also can suffer from inconsistent plastic: if the source material is not chemically identical, unusual results can occur, particularly with color and strength.

Secondly, recycled filament has been subject to safety concerns. Some plastic that was never intended for 3D printer extrusion has been used for recycling, thus introducing potentially toxic colorants into 3D printer workspaces. Without adhering to safety standards, such recycled filament is always questionable.

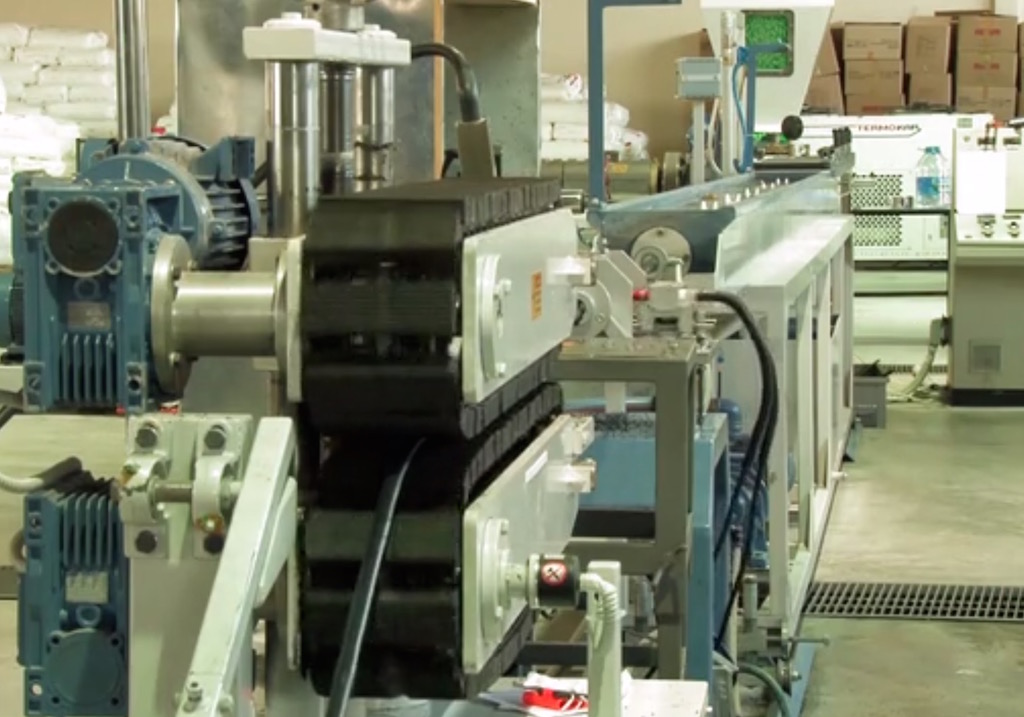

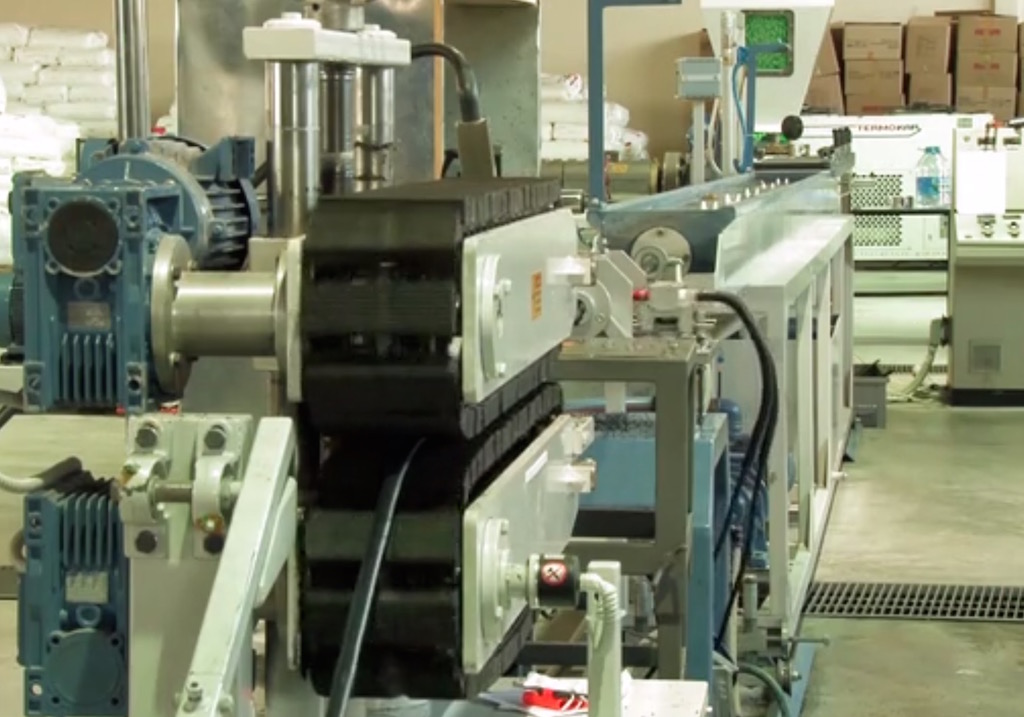

Meanwhile, Dimension Polymers has taken a different approach. Instead of using scraps and rudimentary extrusion gear, they’ve created a fully professional production line (shown at top) that can produce high quality filament. They’ve spent considerable time experimenting with different stakeholders to develop a process that overcomes the “variance of type, grade and consistency”.

So far they’re just marketing a recycled ABS filament. If they succeed, it seems logical they’d pursue other recyclable plastics, such as nylon. It’s unlikely they’d attempt to recycle PLA plastic because it is already a recyclable material: it’s made from organic sources and biodegradable.

Will 3D printer owners prefer recycled ABS plastic? With Dimension Polymer’s price of USD$30 per 750g (or $40 per kg), they seem to be in the mid-range of pricing. Our take on the filament market lately seems to be a drive to the lowest price, making filament a type of commodity material. Dimension Polymers will have to overcome that challenge if they hope to succeed.

Via Kickstarter