Fabbaloo friend Richard Horn has produced a detailed tutorial on how best to produce strong 3D printed parts.

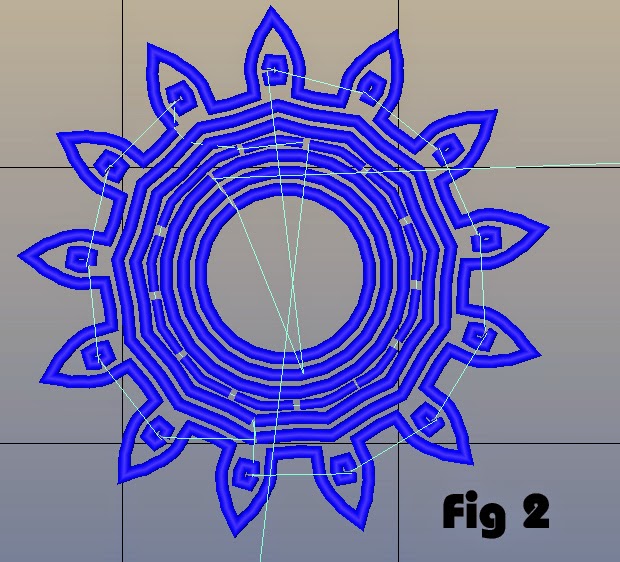

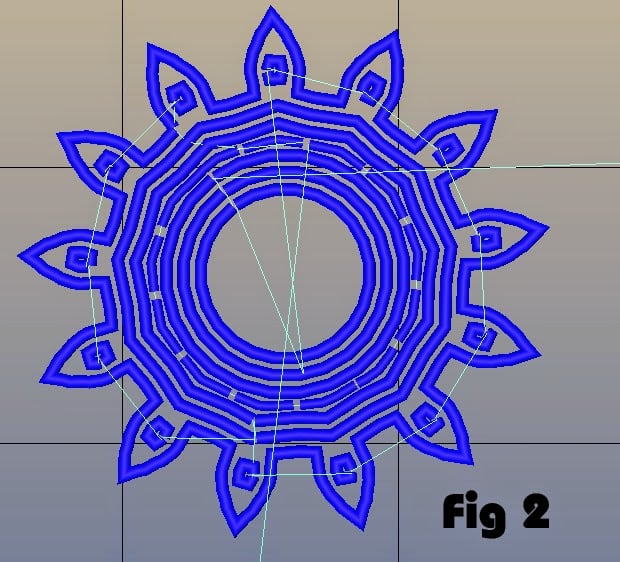

Specifically, Horn (a.k.a. RichRap) demonstrates the analysis required to adjust 3D printing parameters to avoid extrusion patterns that result in weak or unclean parts.

The complexity of slicing software can sometimes deter 3D printer operators from experimenting with different parameter settings. Often people simply take the “default” settings, which can result in poorly formed prints, because default settings may not be optimum for any particular print.

This is especially important if your print is to be used in a stress situation. In Horn’s case, he’s attempting to print strong gears for use in a machine.

Two main goals he’s identified are:

- Ensure the areas requiring strength are made with continuous extrusions, rather than separated segments. There is no strength in gaps, while a continuous extrusion is bonded from one end to the other.

- Ensure the surface finish is relatively smooth by avoiding extruder jumps across the surface, as each jump is likely to result in an unintended surface protrusion.

How is this accomplished? You’d best read his tutorial, even if you’re not planning a project to print mechanical gears, because the insight provided will be useful for almost any print.

For some people, Horn’s concepts will open them up to a new world of printing improvements.

Via RichRap