The prototype 3D printer that’s been installed on the International Space Station has just completed its first round of tests.

In a post on Medium, the team from Made In Space, the manufacturers of the high-flying 3D printer, explain what’s happened since the machine was installed late last year.

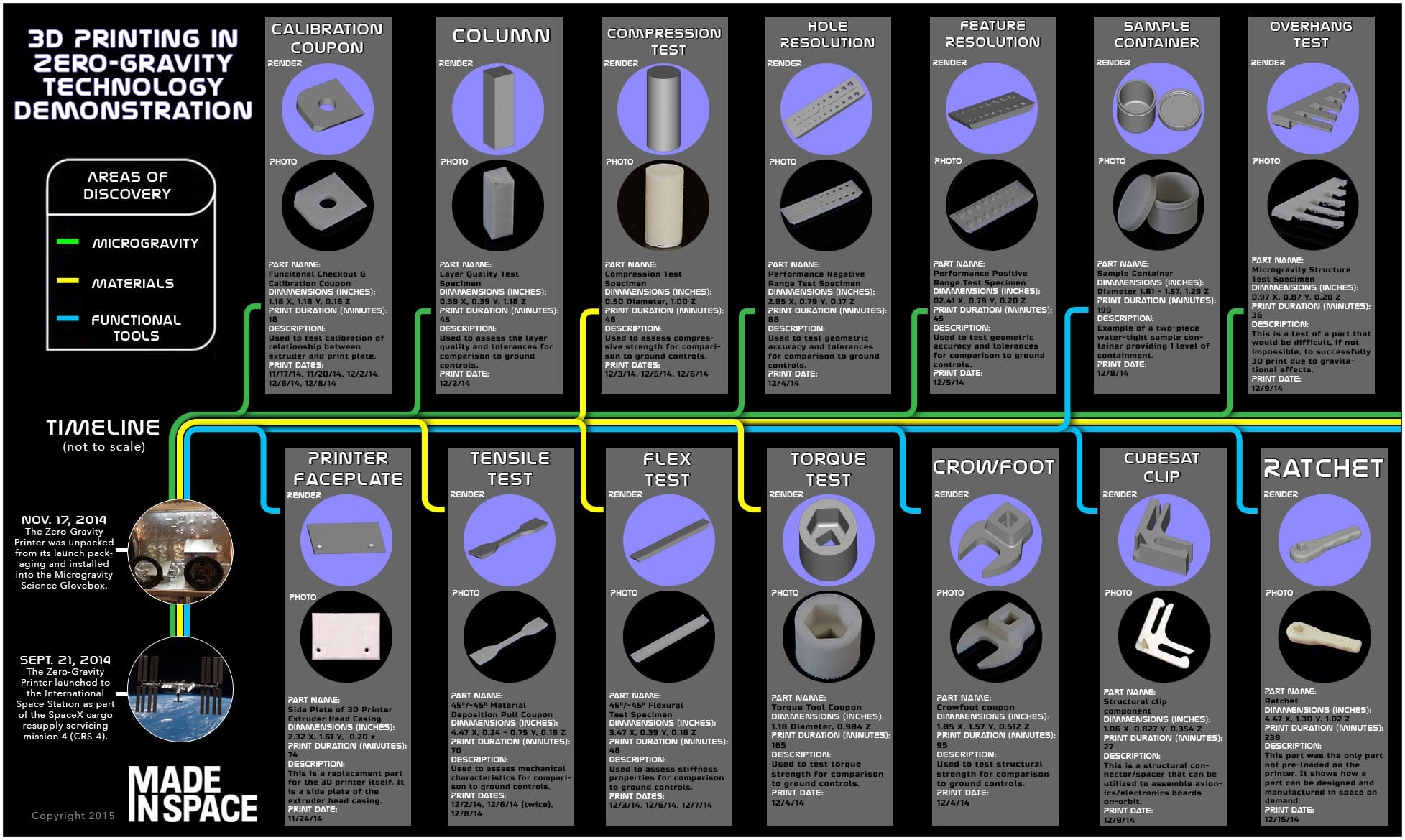

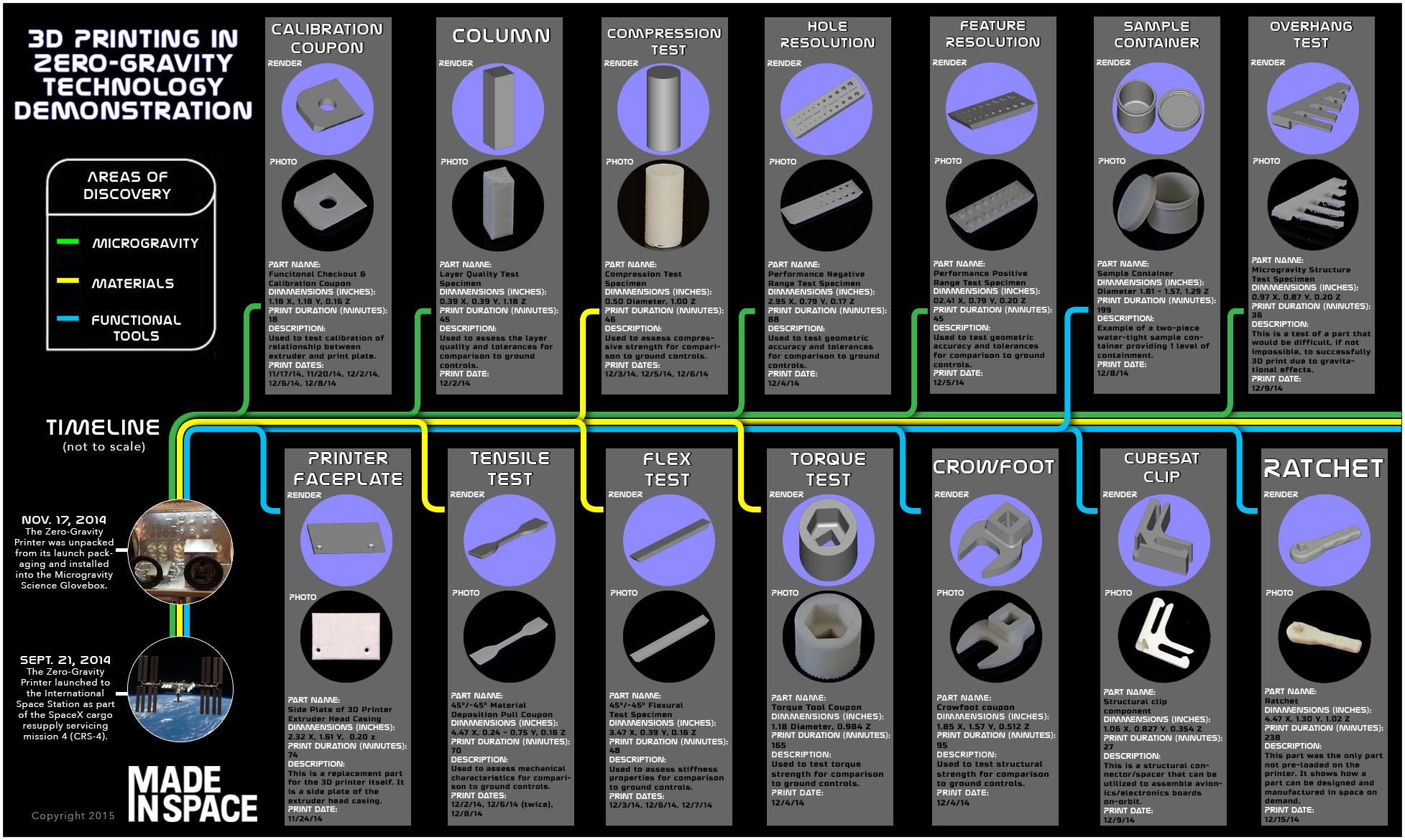

The machine is a first; no similar manufacturing technology has ever been attempted in orbit, so testing was obviously required. NASA and Made In Space created a set of progressively more difficult test objects to produce, each investigating various properties of the 3D printing process as operating in a micro-gravity environment. Beginning with a simple test “coupon” to see if the process worked at all, and ending with a spectacular working ratchet, it appears the Made In Space machine passed all tests. (Note: we duplicated this particular print on the ground.)

In the image at top you can see the specific tests involved. Most items were printed only once, but a three were printed multiple times (calibration coupon, tensile test and flex test) in order to determine consistency from print-to-print.

Here is the most startling finding of this series of tests: every single print attempt worked perfectly without incident.

This is an unprecedented happening. As anyone who uses a 3D printer on the ground knows, prints fail, and fail often, no matter what kind of machine you happen to be using. While the less expensive and less sophisticated machines may fail more frequently, the high-end industrial machines are also known to fail.

The Made In Space printer performed no less than 25 consecutive, fail-free prints. We would have a very difficult time printing 25 items on any ground-based 3D printer.

The reason for the success is more than likely an extreme attention to detail, calibration and process, in the way that NASA does everything they do. When you’re off-planet, it had better work – and they make certain it does.

The moral of the story here is that with similar attention to detail, calibration and process, ground-based machines might significantly improve their reliability. Perhaps it’s time to check out the workflow you use when 3D printing?

Via Medium