Solidscape claims they hold some 75% of the 3D printing market for jewelers.

It’s perhaps not a surprise, given their extensive product line. The company manufacturers no less than four different models of high-resolution 3D printers specifically designed for producing jewelry.

Solidscape explained to Fabbaloo that the market for customized rings is booming, particularly among independent corner jewelers, who now, with the 3D printing technology currently available, can produce highly customized products for their clients. In the USA alone there are over 25,000 small independent jewelers.

Solidscape’s machines print in wax, which is used by jewelers to create metal objects with a traditional lost-wax process. But there’s more to jewelry printing than just wax. Platinum, for example, requires very high-precision molds.

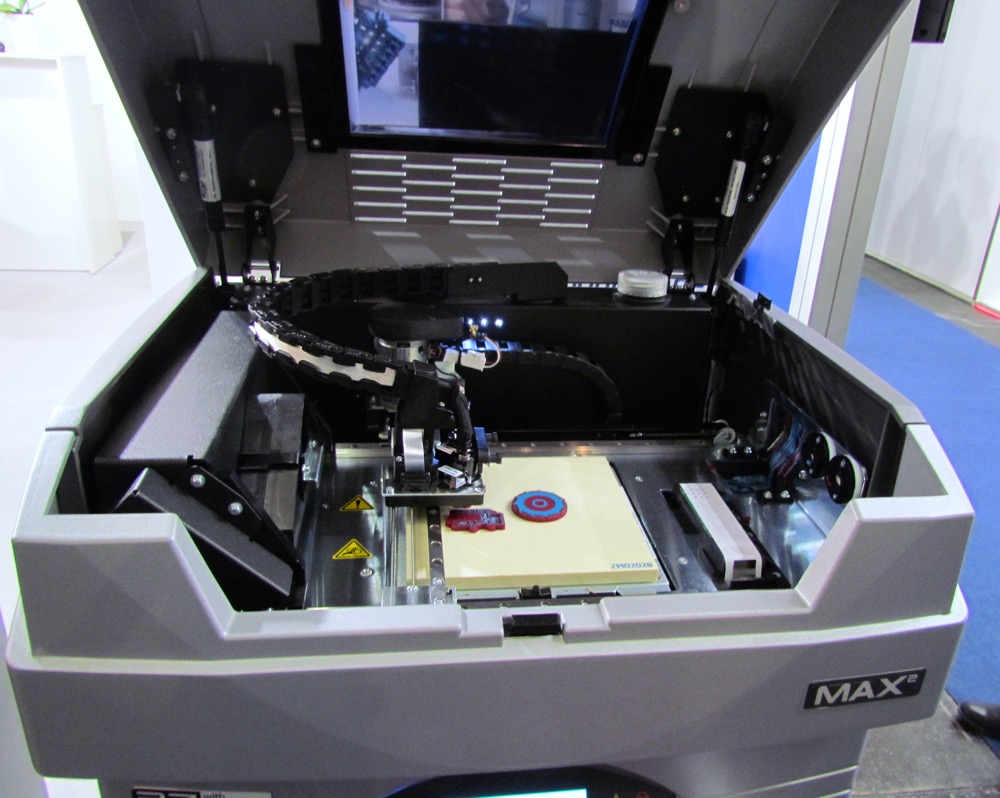

Their product line includes four models, the 3Z Lab, 3Z Studio, 3Z Pro and their latest, the MAX2, each designed for different applications. However, each machine offers similar printing characteristics: a build volume of 152 x 152 x 152mm, and a layer size of around 3 microns (0.003mm). These machines are truly production machines, with an ability to run unattended for up to 72 hours straight. The largest unit (MAX2) is priced at USD$55,000, while the others are somewhat less pricey.

Solidscape explained how a metal model is made from a wax print, as shown above. On the left is the print as it emerges from the Solidscape printer, including its support material. This is easily dissolved, revealing the actual model print (middle). Finally, this model is used to cast a metal equivalent on the right.

So far, Solidscape says they’ve placed some 4,000 printers into the market, with many more planned.

Via Solidscape