A project by Poland’s Fucco Design created replicas of large church figurines in wood.

The project was to replicate – in wood – historic religious figurines for a church display. Traditionally, this would have been done using woodcarving techniques, but Fucco Design was charged with using modern approaches to create the replicas.

They chose to do the job with 3D printing. It’s possible the replicas could have been made with modern CNC milling technology, but some of the objects’ geometry could have posed challenges to CNC equipment.

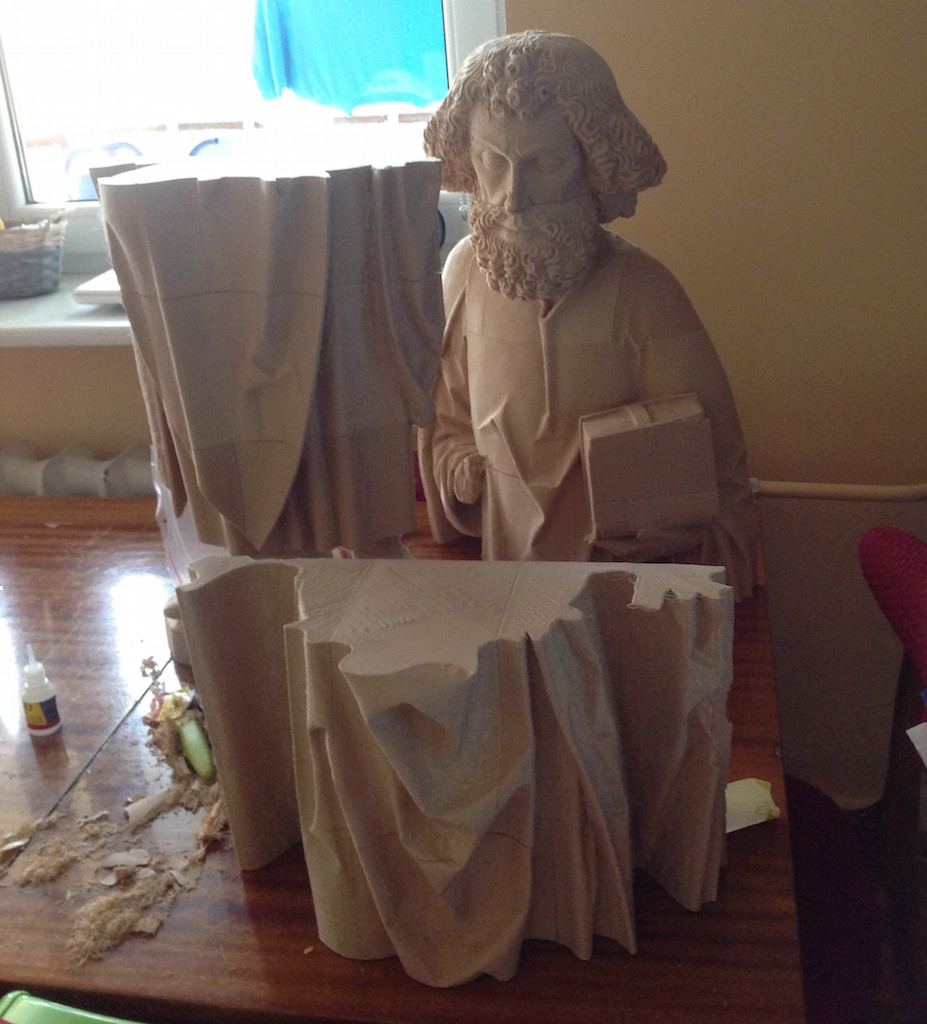

The replicas are large. One final piece was 153cm tall, far larger than almost any 3D printer available. They also had to be made from wood, presumably to match the related items in the final display as shown above.

Printing in wood was achieved by using colorFabb’s woodFill filament, which is a mix of polymer and wood particles. Fucco Design’s approach was to segment the scanned 3D models into 78 separate printable pieces. Printing was performed by three personal 3D printers: an Ultimaker Original, an “Exxtrudo” (made by Fucco Design themselves) and the majority of the work done by a reliable MakerBot Replicator 2.

Printing the 78 pieces apparently took a lengthy 624 successful print hours, but the elapsed time was less as the work was distributed over three printers simultaneously. On average, each piece took eight hours. colorFabb provides full details on parameters and methods used to make this successful at the link below.

Once assembled, the print assemblies were finished in traditional ways to enable it to fit smartly with the rest of the display. You’d never know they were 3D printed.

We believe this project demonstrates the ability of almost any 3D printer to print large objects. You simply segment, print and assemble. However, a project as large as this is something you’d have to plan carefully, but as they’ve shown here it is entirely achievable. What will be your next giant print?

Via colorFabb and Fucco Design