Hidden in a very obscure corner of EuroMold was a 3D print like no other we’d yet seen: a machine that included a filament extruder AND a DLP resin projector.

The curious machine was produced as a prototype by a team at the University of Darmstadt. As of our viewing, the machine had actually not yet been tested, but it definitely had been assembled.

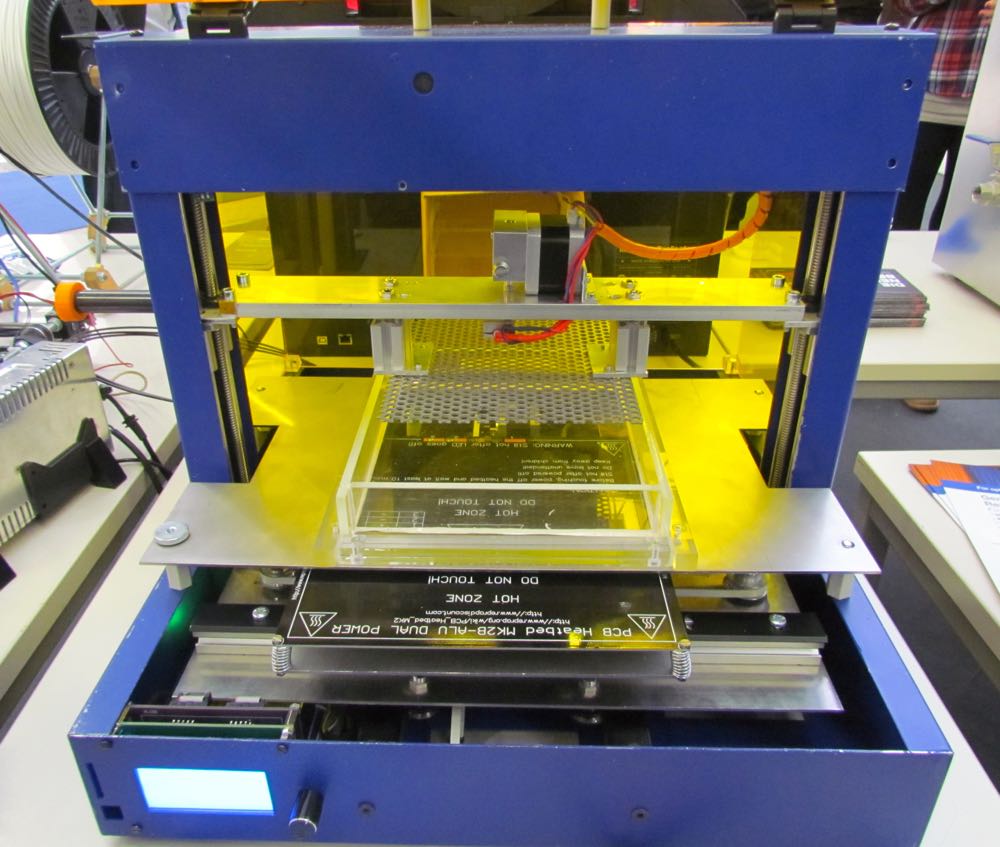

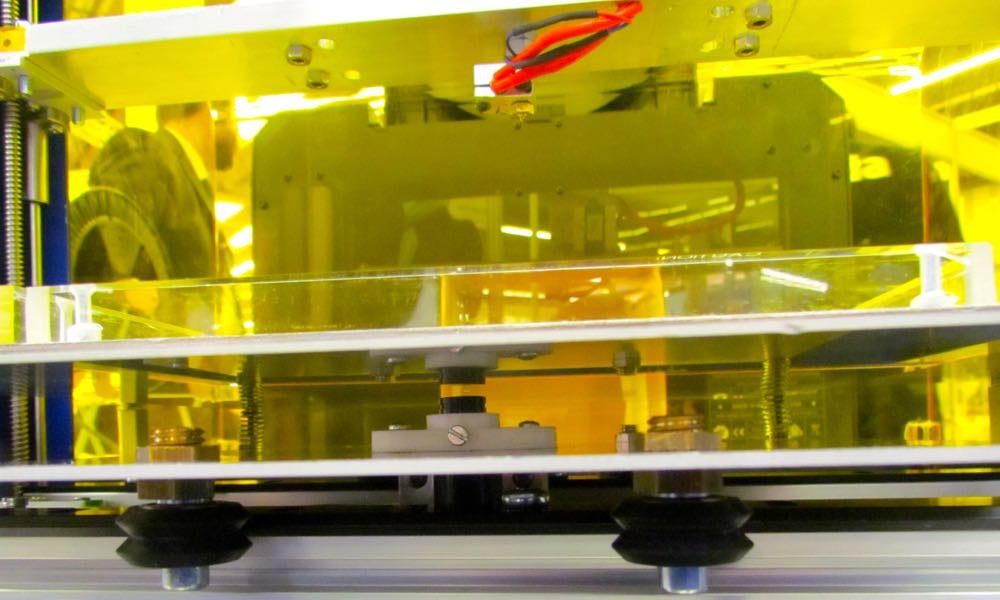

It’s not a large machine and has relatively average specifications for each of its two modes. In fact, the laser is said to be a bit “slow”. You can see the laser at the bottom under the resin tank in this image.

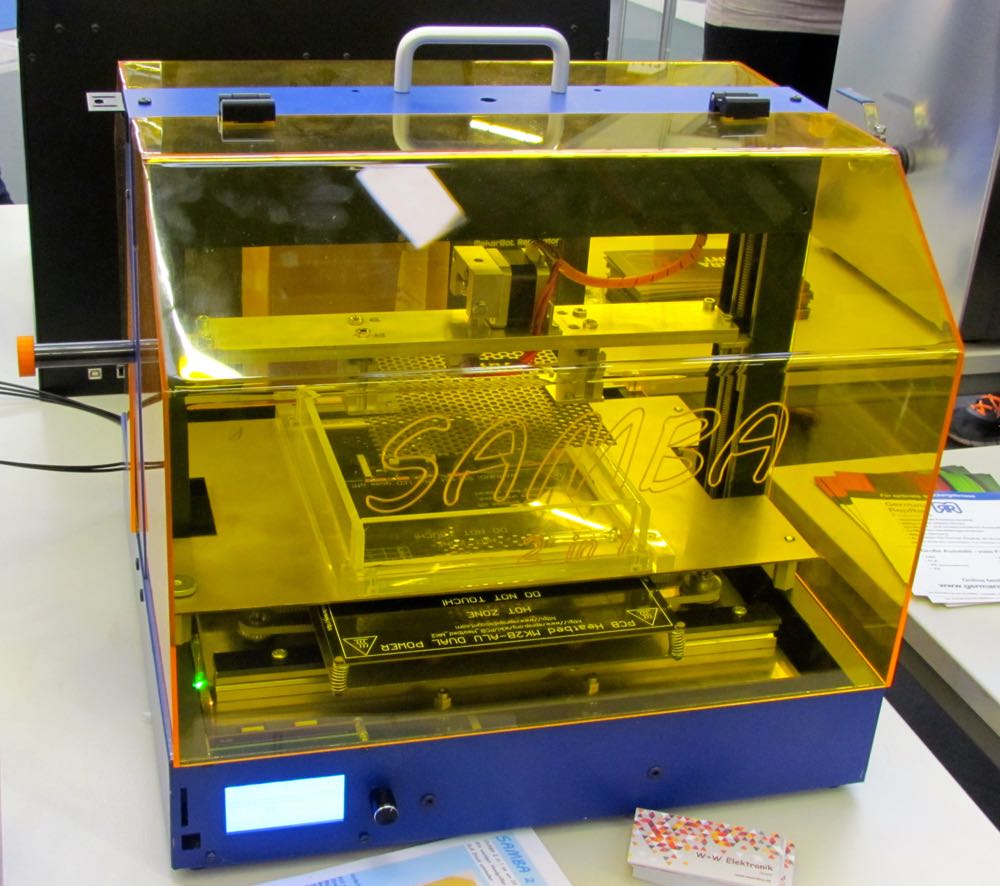

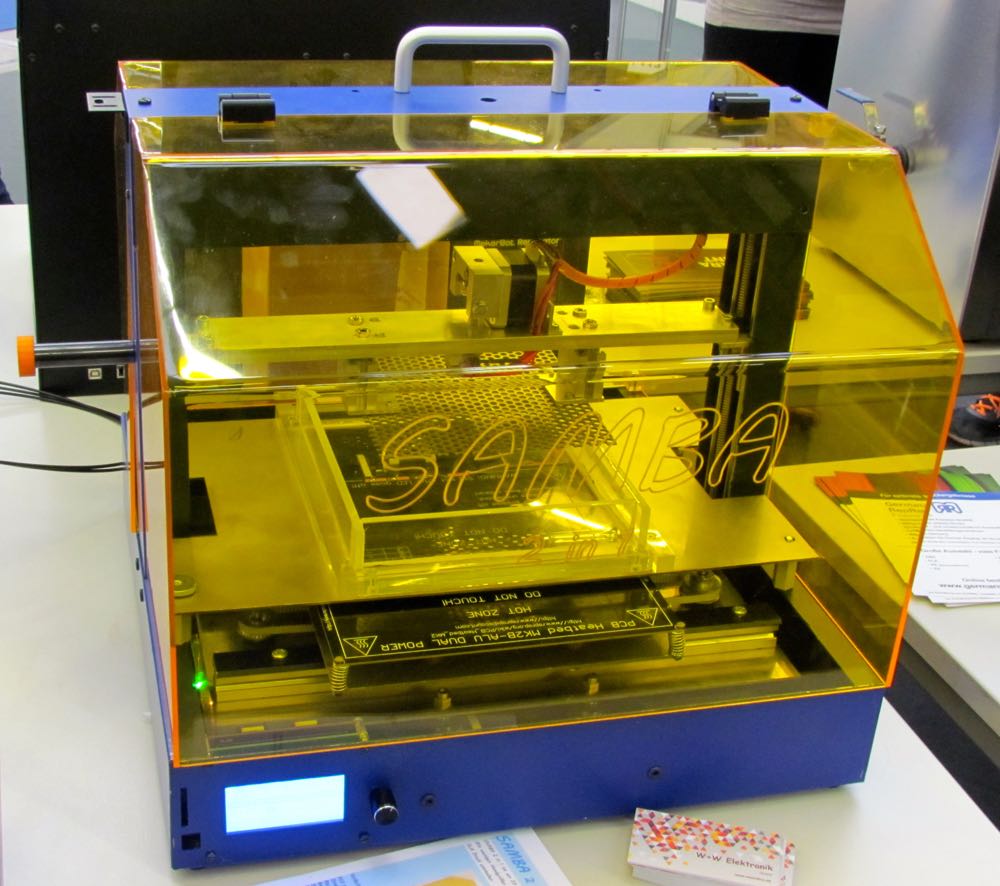

However, there are some interesting side-effects of coupling two 3D printing processes within a single box. One we noticed was the UV-resistant amber-colored case, which protects the resin from accidentally solidifying from stray UV sunlight. While this case encloses the core for UV purposes – it also creates an enclosed chamber that can provide a controlled heat environment for printing.

You cannot use both processes simultaneously. Instead you may choose one or the other per print, based on the requirements. If you require a small, delicate object with very fine details you might engage the DLP resin mechanism. On the other hand, if you require a strong ABS part, you’d choose the filament extruder.

The Samba 2 in 1 is only a prototype with much testing and tuning yet to happen. However, we were told the intention is to begin selling the device in first quarter 2015. That’s not very far away. No word on pricing, but as the Samba 2 in 1 is produced by a small startup company, there won’t be many units available.

Our questions are straightforward: is it important to have two processes in one machine? Would it be a better alternative to buy two machines, each using one process in a more refined manner, than having them in a single machine? How will Samba’s price affect this decision? We can see this concept succeeding only if the price is far less than buying two machines.