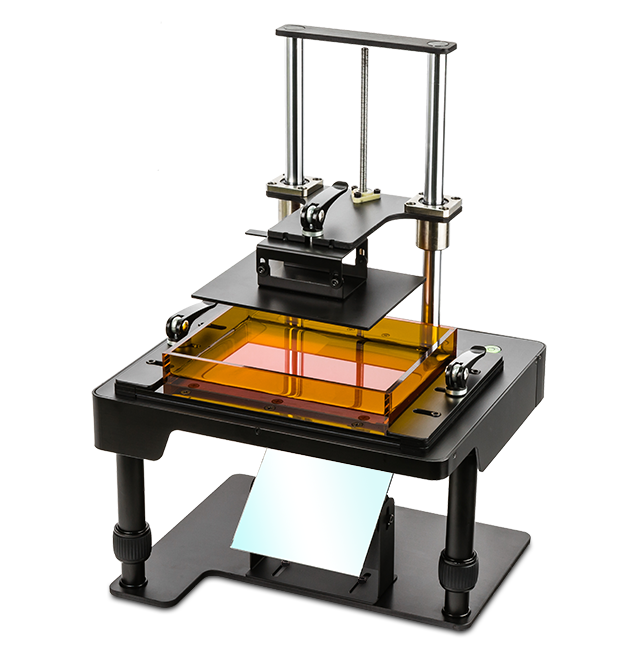

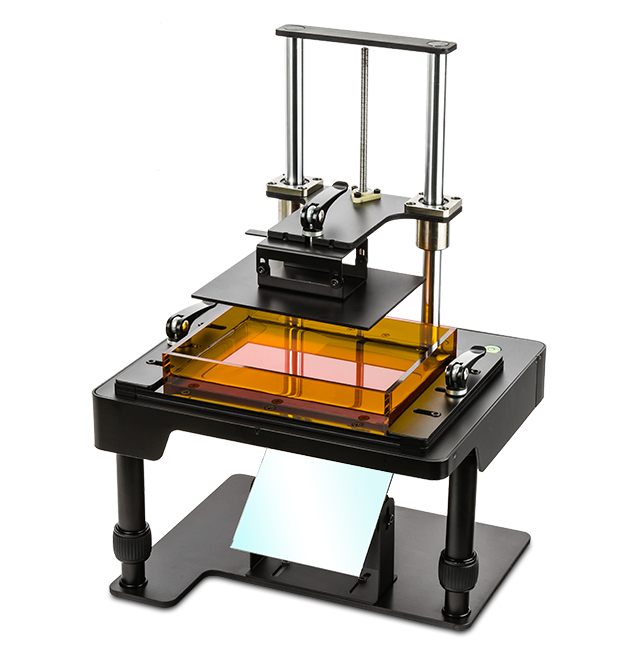

Need a high-resolution 3D printer? You can now purchase the Solus 3D resin printer.

We examined this machine a few months ago, but yesterday they launched their official crowdfunding campaign on Indiegogo.

As expected the launch price of this capable unit was just under USD$1,000. However, that was for the first ten units, which are long gone now. Additional batches are available at USD$1,099 and USD$1,199, depending on how fast you act.

The machine specifications have not changed since our last look, but their campaign goes into much more detail about the required projector. While the Solus is an assembled unit, you must provide a separate non-LED DLP projector to get it going. The project explains a number of different options and their implications. For example, a cheap SVGA (800×600 pixel) projector will yield a resolution of 0.150mm, whereas a full HD projector (1920×1080 pixels) can produce prints with resolution as low as 0.025mm. At that size, you really can’t see any layering.

The project also explains a bit more about their peeling mechanism. This seems to be one of the key factors that differentiates resin 3D printers: how, exactly, does one release a print from the bed? Resin 3D printers typically print very finely detailed small objects that are quite fragile. If the bed release mechanism is too violent, your print could get destroyed in the process.

Reify3D, the makers of Solus, believes their approach is their “biggest breakthrough”. They say:

Most other consumer SLA printers use either a PDMS silicon layer or an adhesive-backed Teflon film for their non-stick peeling surface. PDMS has great non-stick properties, but it can get cloudy or even break after just a few prints causing much frustration. Adhesive-backed Teflon can scatter the light, causing washed-out details or the Teflon can quickly separate from the tank bottom causing print failure.

To solve these issues the Solus uses a durable film sourced from the semiconductor and flat-panel industries in combination with a patent-pending tilt peeling method. This smooth peeling and unscattered light transmission allow for sharper details, XY features below 100 microns and a very smooth surface finish. With this peeling method, we have also been able to print single objects that almost completely fill the build area (14.5 x 11 cm), all while eliminating the need to change or re-coat the resin tank.

This approach could indeed provide improved results. The sample prints appear to have excellent resolution.

If the Solus sounds like an interesting machine, by all means check them out at the link below. However, as it is being offered through a crowdfunding campaign, we must remind everyone of the risks. Many crowdfunding projects never ship products. Solus may be entirely successful, but remember there are risks.

Via Indiegogo