Many of our readers enjoy building their own 3D printers. Now there’s a key component with significant benefits.

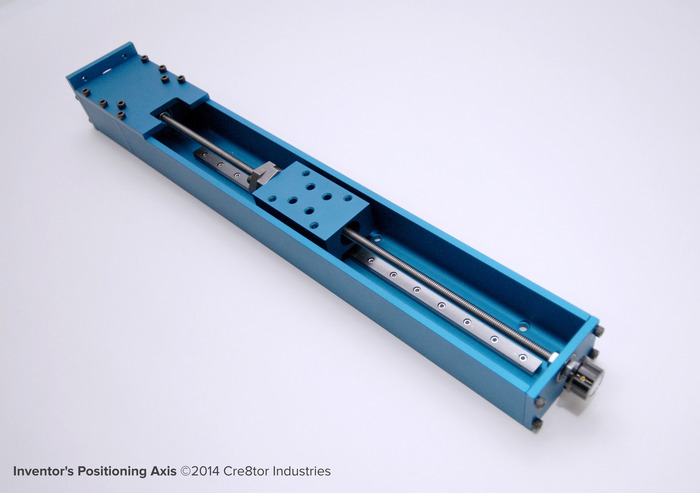

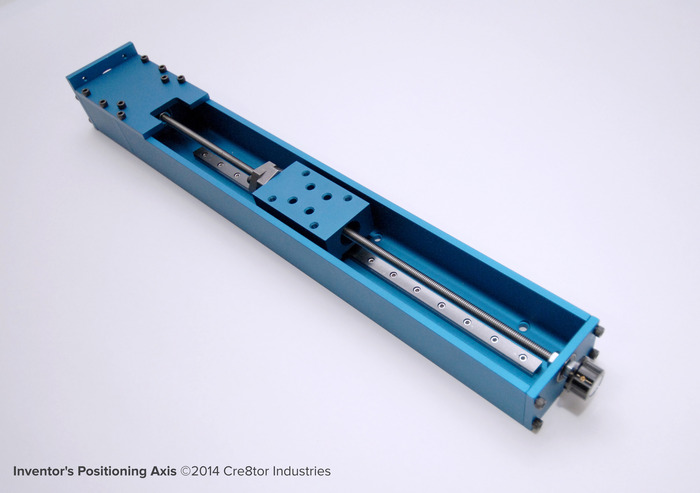

It’s the “Inventor’s Positioning Axis”, a precision linear rail guided positioning axis. Three of these arranged appropriately could accurately guide a 3D printer extruder around a build volume in three dimensions.

The benefit of this component, aside from the fact that you’d not have to build it yourself, is that it provides tremendous positioning accuracy. They claim 8 microns accuracy (0.008mm) with only 2.5 microns backlash (0.0025mm). (Backlash is the “play” between adjacent mechanical parts when sudden movements occur. If you have high backlash, you’re accuracy is compromised.)

The axis can be used not only for constructing highly accurate 3D printers, but also any device requiring precise mechanical motion. This could include 2D devices such as laser engravers or other 3D CNC machines.

The folks behind the project, Michele and Jim Gray of Portland, explain the reasons behind the project:

When we were building our CeramiCast 3D printer, we were disappointed in our options to purchase a pre-made linear axis. There are a few tools available, but the existing tools only fit big business budgets. We decided to construct our own, using the resources available in our pattern shop, and created the product that we had been looking for at an affordable price.

The availability of such precise components could simplify things for those designing and building quality 3D printers. It’s possible we may see this component appear in upcoming new personal 3D printers.

For now, however, you can order one of these (or more likely three of them) from the project’s Kickstarter page, where early birds can nab them for as low USD$150 each. Prices will rise as sales occur, so get them while you can.

Via Kickstarter