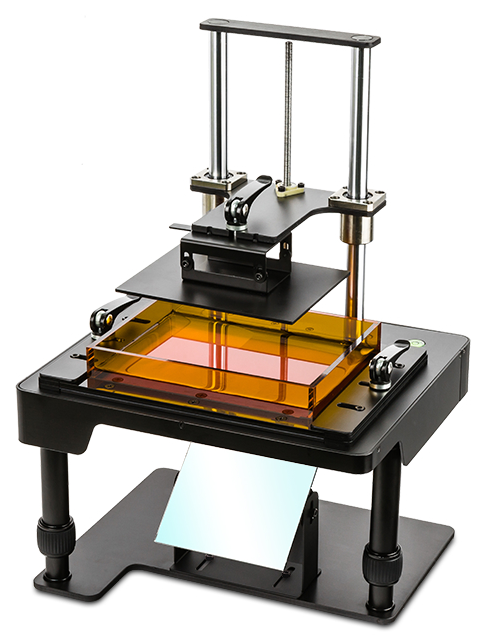

We’re looking at another resin-based personal 3D printer, the Solus, by Taiwan-based Reify. It’s a little bit different from the competition.

There has been an avalanche of resin-based 3D printers this year, given the recent expiration of related patents. Some machines attempt to market an ultra-low cost model, while others go for extreme performance. The Solus seems to be a mix of both.

Like some of its competition, the Solus requires an externally supplied DLP projector. This can lower the price of the printer if you happen to have access to such a projector. The Solus can use either a standard XGA (1024×768) or HD (1920×1080) projector, with the HD version providing additional print resolution.

The Solus is robustly constructed, being made from steel, aluminum and high-quality components. This should be a given, considering the high accuracy delivered by the Solus. In “XGA” mode, the Solus can print XY resolution of up to 50 microns, (0.050mm), while in “HD” mode it can go as fine as 25 microns (0.025mm) in the XY axis. The Z-axis layers are as small as 1 (ONE!) micron (0.001mm).

The build volume is a bit tricky to specify, as it changes depending on the DLP mode and selected resolution. The most “coarse” resolution, if we could call it that, is obtained when printing at 0.140mm XY in XGA mode, yielding a build volume of 145 x 110 x 200mm, which is quite large for a resin 3D printer. At the other end of the scale, the finest resolution occurs when in HD mode printing at 0.025mm XY, where you’ll be able to build objects up to 48 x 27 x 200mm. In fact, the Solus’ adjustable legs provide an ability to achieve a wide variety of resolutions and build volumes between these ranges.

One of the trickiest problems using a resin 3D printer is the method by which prints are peeled off the print surface. If stuck too well, you’ll likely break the print prying it off the bed. Reify has developed a special method of doing so, according to founder Mark Kuhnlein, who says:

Our greatest effort went into creating a peeling system that allows the user to print large, highly detailed or minute objects while eliminating the need for replacing or re-coating the resin tank. To achieve this, we drew on our team’s expertise in the flat-panel and semiconductor industries to source a material with high strength, excellent chemical resistance and a low surface energy. We have named this patent-pending tilt peeling method TUF due to its durability.

The Solus is not yet available for purchase, but it looks like a very interesting option for those seeking an inexpensive resin 3D printer. We’re told the price will be near USD$1,000 for a basic model and USD$1,300 for one including an XGA projector when their Indiegogo campaign launches soon.

And when you’re finished printing, you can repurpose the DLP projector to watch the big game.

Via Solus