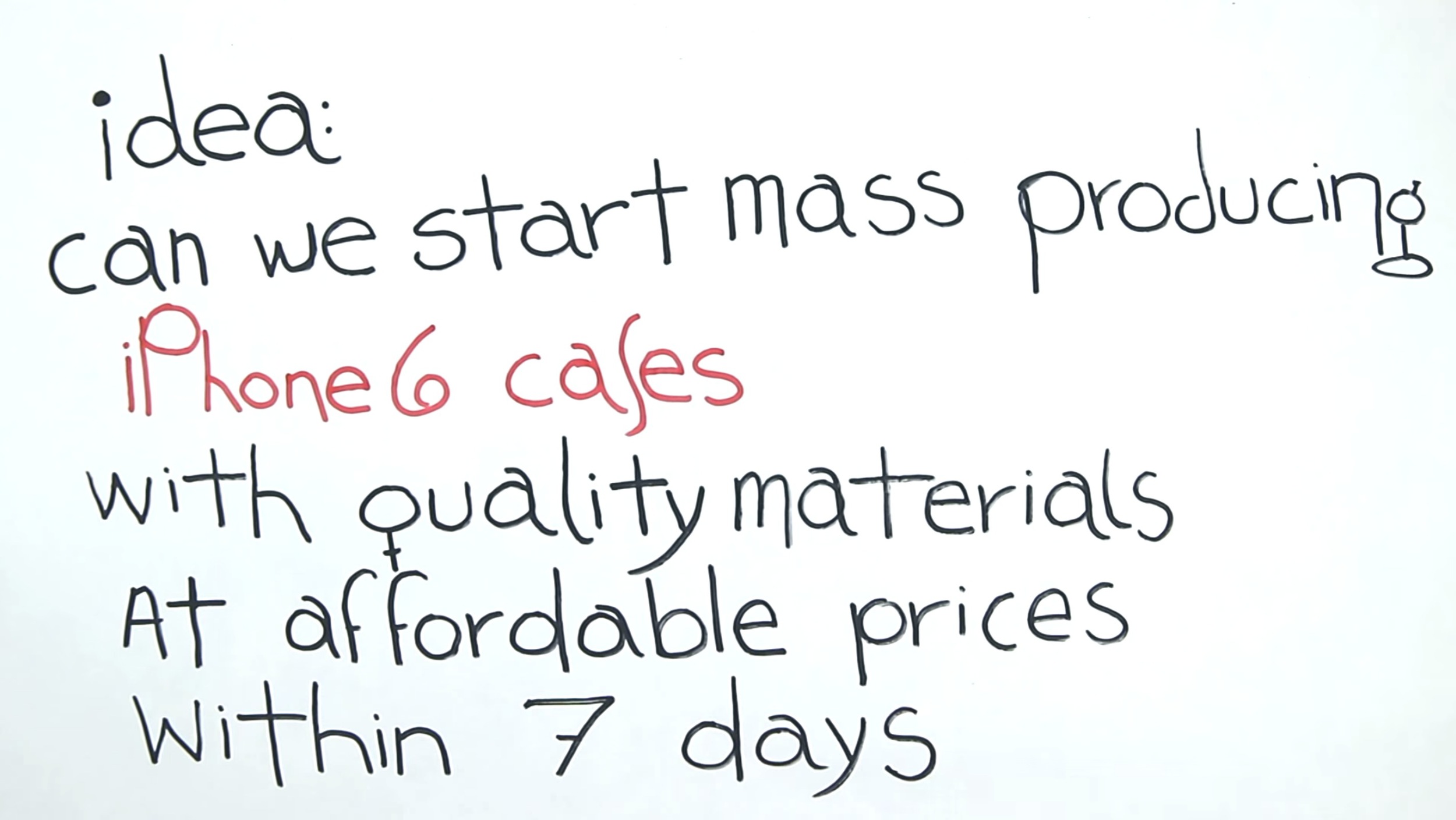

WHYcase demonstrated the true power of 3D printing by creating a brand new manufactured product in only 7 days.

The product is an iPhone 6 case, which explains the need for speed: the phone was announced in September and cases were required by the millions who purchased them. It’s a clear plastic case, maintaining a view of the phone itself. The case was manufactured using standard injection molding processes.

But wait – how could you produce a mold for the injection molder in only a couple of days? The answer is revealed in their video.

The company 3D scanned an iPhone 6 to obtain a very precise measurement of the required shape, from which a 3D model was developed. This was then inverted and 3D printed using an EOS metal 3D printer to produce a raw mold. We say “raw” because 3D printed metal is rough and definitely not sufficiently smooth to be used as a commercial mold. WHYcase had to polish it to perfection, whereupon it was used to produce the new cases.

Could this be an example of how manufactured products could be rapidly developed in the future? We think so – so long as the product is a simple object. Products including electronics, mechanical movement or chemical reactions would obviously require considerably more effort.

Via WHYcase