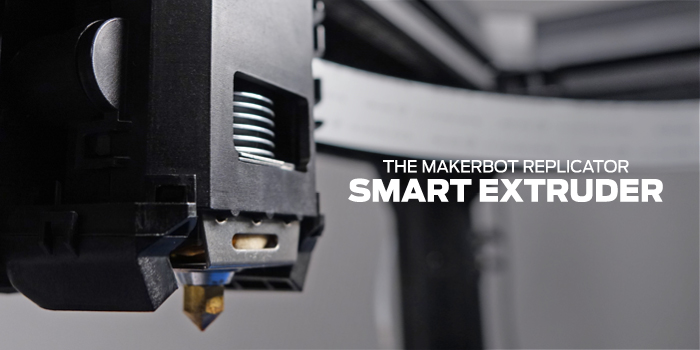

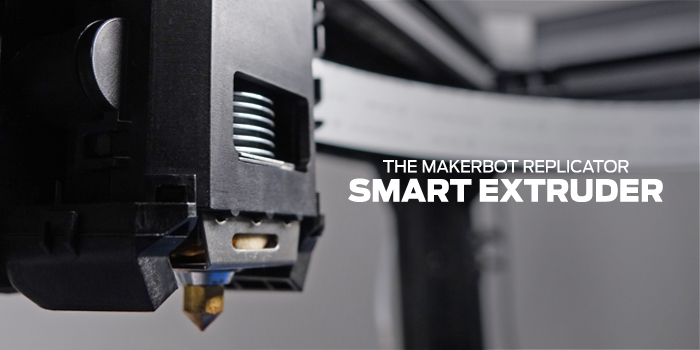

MakerBot introduced an advanced extruder earlier this year, but it seems people are having trouble with it.

In a post on MakerBot’s blog recently, the company explained the “Smart Extruder” was designed to address these specific issues frequently encountered by 3D printer operators:

-

Workflow: When an extruder stops, work stops

-

Time: Customers don’t want to interrupt work to service extruders

-

Wear: Extruders naturally wear out

It included features that directly address all of these symptoms. However, we’ve heard anecdotally of issues people have had with the device and it appears MakerBot has as well. It may have even led to some customers returning their machines. They say:

We’ve heard from some of you that you’re having challenges with your Smart Extruders. As avid 3D printers, we understand the frustration of failed prints and lost time. We get it.

They provide additional instructions on how to best operated the extruder, specifically to prevent clogging. It seems that many clogs are caused by operators short-cutting the load/unload procedure, or by prematurely turning off the printer before the cooling sequence can be completed.

Perhaps these are hints at potential features for next year’s MakerBot announcements, which we expect to hear in January at CES. In the meantime, MakerBot Gen 5 owners should best follow instructions. In fact, such procedures are probably good for any other 3D printer, too.

Via MakerBot