We don’t normally write about mills, but we will about this one because it is 3D printed.

A mill differs from a 3D printer in that it starts with a block of material and carves it down into the desired object. That’s subtractive manufacturing, as opposed to the additive manufacturing process used by 3D printers.

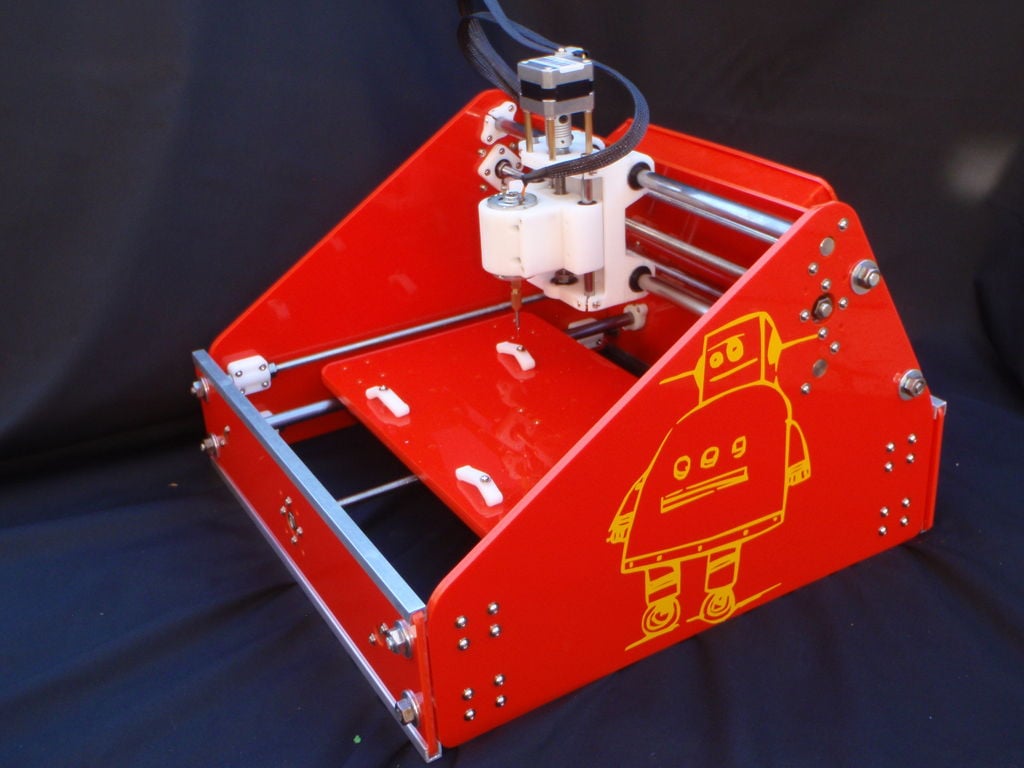

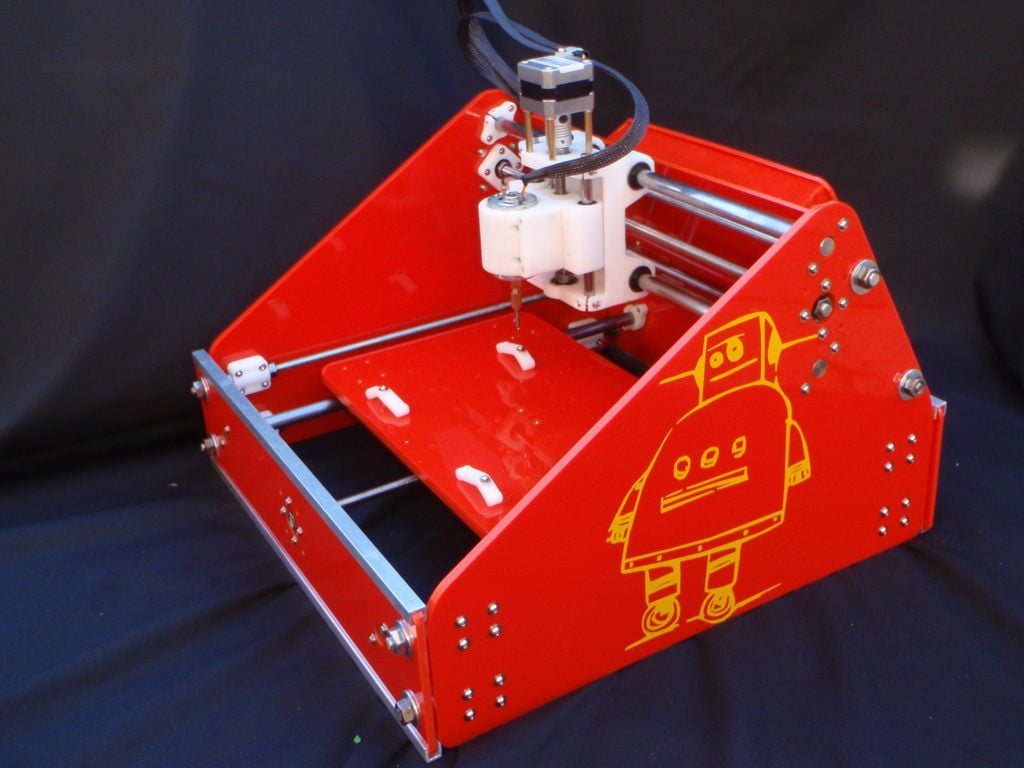

In this case, we’re reporting on an Instructable explaining how to build a mini-CNC mill using 3D printing. Certainly the whole mill is definitely not 3D printed; instead just key components are 3D printed, while others, such as the case, are laser cut, and others are off-the-shelf electronics or mechanicals.

The 3D printed components include the key clamps, mounts and holders for the mechanical portions, tool slide and Z-axis apparatus. It turns out that 3D printing is the easiest part of the assembly process; you simply await completion of the 3D printed parts, while assembling them into a working CNC could take much longer, depending on your skill level.

Some people use their 3D printers to print parts for a new 3D printer – but here you can print parts for a very different making machine.

Via Instructables