Owners of Formlabs personal 3D printing gear rejoice! The company has announced two new materials with powerful properties.

Up to now Formlabs 3D printer owners had a rather limited choice of resins for use in their Form 1 or Form 1+ personal 3D printers: Clear, White, Grey or Black resin that produced hard objects. Useful, but not truly leveraging the platform as much as we could imagine.

Today the company announced the availability of two new resins that work in all existing Formlabs equipment. Actually, they term they use for the new materials is “new families”, suggesting there’s more to come.

Castable resin permits the production of detailed prints to be used to create molds. Here’s how it works: print in castable material, encase in plaster, burn out the castable model, leaving a hollow in the plaster in the exact shape of the original printed model. The hollow becomes a mold that can accept liquid metal, latex or other liquid curable substances. Just remove the mold and you’ll have a complete object. Check out the process in the video above.

This enables owners of Formlabs equipment to attempt production of jewelry or metal parts, assuming you have access to a furnace capable of melting metal. You can now make items such as this ring – but you’ll have to provide your own gemstones.

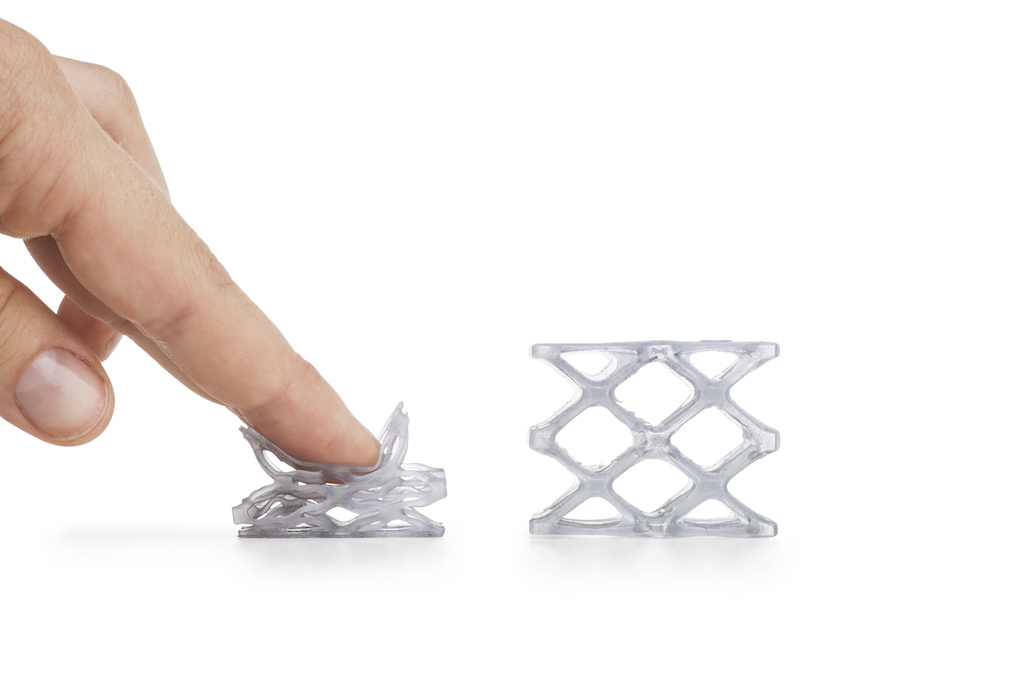

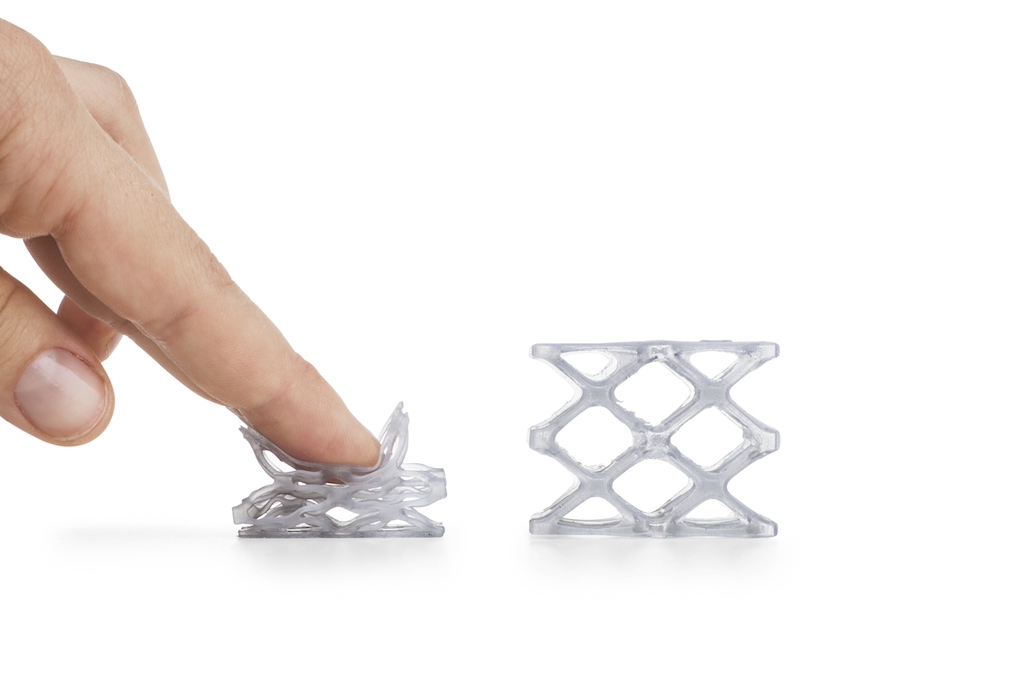

The other material announcement is Flexible resin. While it’s liquid before printing, the Formlabs 3D printers can cure it into a flexible “rubber-like” solid. You’ll now be able to directly 3D print gaskets, flexible hinges, small tires, rubber grips and much more.

With a combination of available resins, a Form 1 owner could now attempt some very interesting projects, far beyond the capabilities provided by the previous multicolored material options.

We suspect some adventurous Form 1 owners have experimented with unusual resins from third parties, but in this case the resins have been developed specifically for use by Form 1 3D printers, so results should be predictable and reliable.

The Castable resin is available immediately, while you’ll have to wait until December for the Flexible resin.

We’re very happy Formlabs has taken this step. While most people are fascinated with the machinery of 3D printing, it’s really the availability of multiple materials that makes things most interesting. Formlabs co-Founder Maxim Lobovsky says:

At Formlabs, we’ve always considered the materials to be just as important. A library of functional materials has always been part of our plan, we’re pleased to introduce these resins to the world.

Welcome to the universe of multiple materials.

Via Formlabs