It’s time to make it clear to everyone who asks: 3D printing isn’t mass production.

We often find ourselves explaining or demonstrating 3D printing to newbies who have somehow not previously encountered the technology. Inevitably, after the “how big can I print” question, is the statement that 3D printing will never overtake traditional mass production.

That could be true, but that’s not the question. These folk are simply having a knee-jerk reaction to the notion that 3D printed objects are pretty expensive when compared to common mass produced widgets. 3D printing also takes far longer to complete than mass production, too.

Mass production is just that: making an awful lot of the same item. That is not what 3D printing is for; It’s a technology for producing unique or custom items at very low volumes.

In other words, economically producing arbitrary objects in quantities not feasible with mass production techniques.

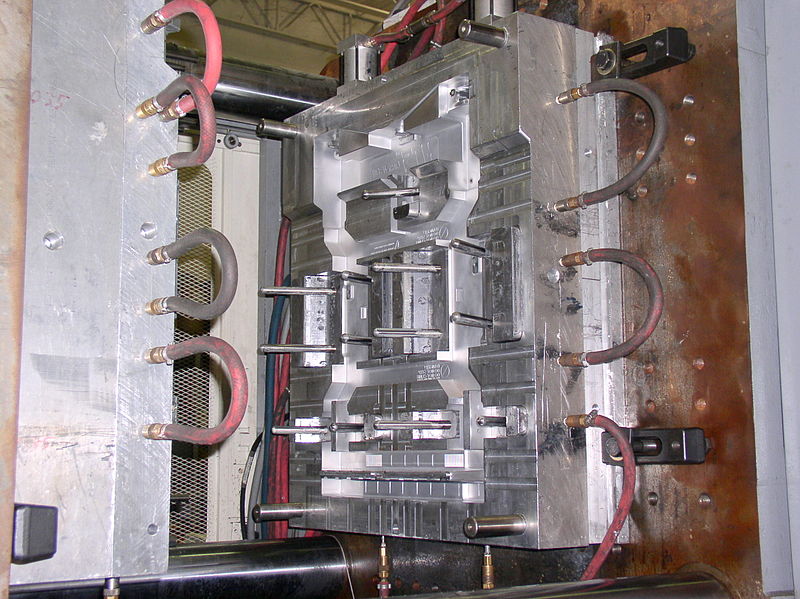

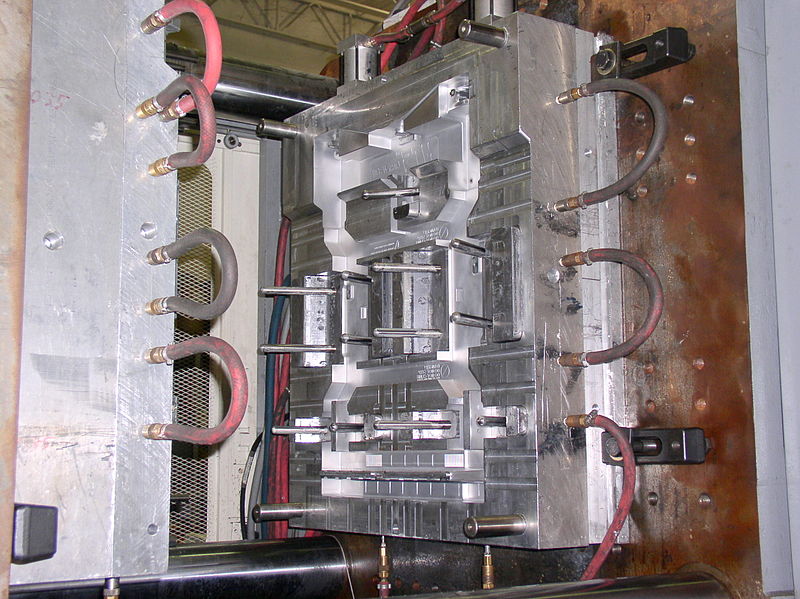

To make an item using mass production techniques, you must invest a substantial amount of cash to “tool up” the production line. This means making injection molds or other fixtures and jigs, and it can be quite expensive. It makes no financial sense to do so if you only need a hundred items. Or ten.

Or one.

They say 3D printing might be the “second best way to make things”, with a traditional way being the best for any specific type of item. That may be so, but traditional approaches cannot make “almost anything” in the same way as 3D printing might.

3D printing is not mass production. It’s custom production.

Image Credit: Wikipedia