We’re checking out the details on a new personal 3D printer that uses a very unusual approach we haven’t seen before.

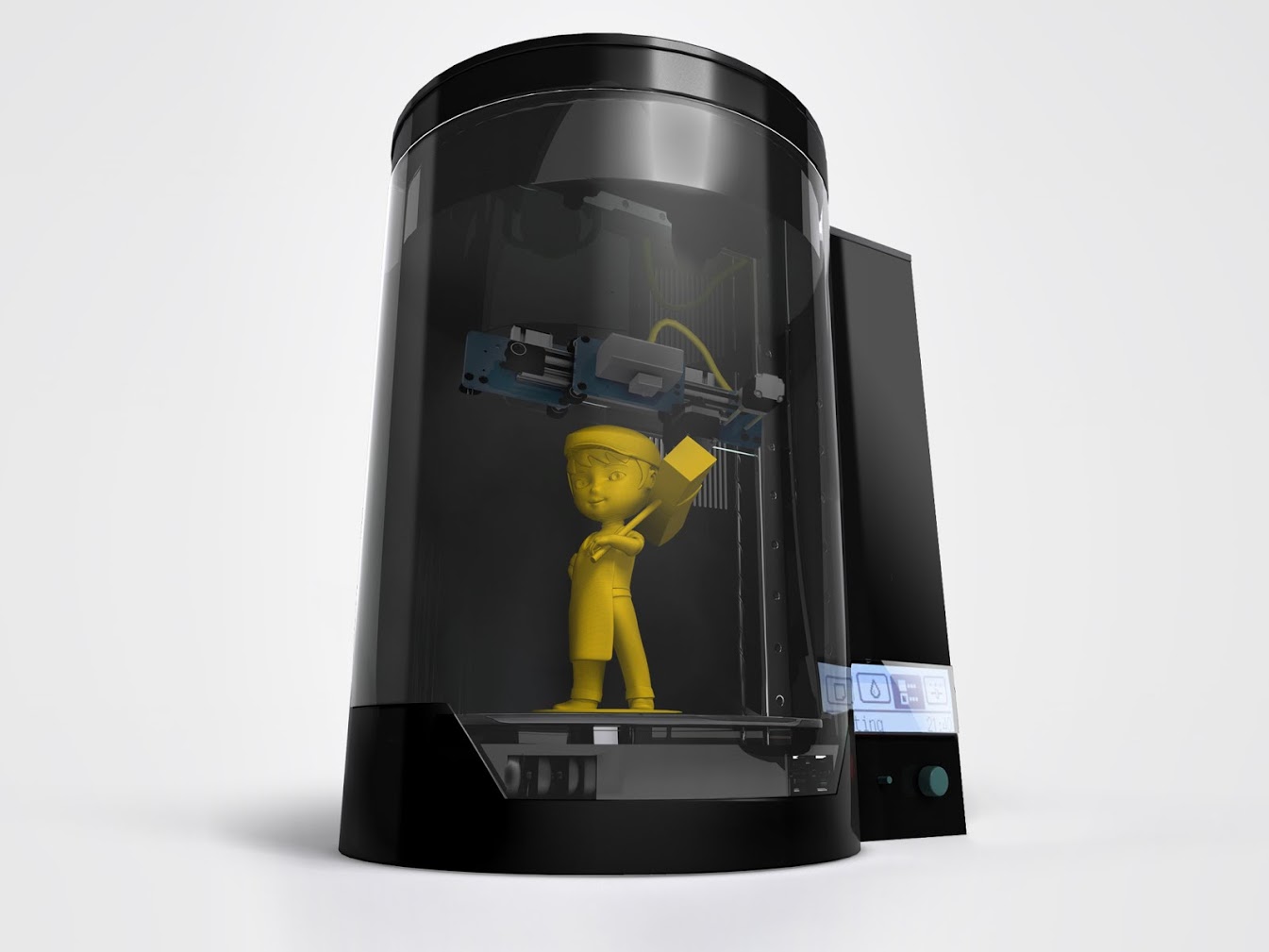

The Blacksmith Genesis 3D printer, designed and built by some folks from Singapore uses a rotary platform for extruder movement. Most 3D printers use a cartesian system in which involves a 3-way X/Y/Z linear axis movements. But the Blacksmith Genesis’ rotary platform is different. They liken it to a spinning record player, where the arm becomes an extruder. This is the third major approach to extruder movement, joining with Delta Robots.

This approach simplifies the mechanics in that the extruder needs only access half of the build volume; the rotation of the platform brings the remaining half within range as it rotates. Thus, there are only two cartesian-style movements: a half-length arm extension and the traditional Z-axis vertical movement. Add those to a rotating platform and you have full access to the build volume. One concern we may have is that the printed object is being moved around and it may come dislodged as we have seen with other approaches involving moving build platforms. However, the movement here is rotary, rather than the jarring back-and-forth cartesian events.

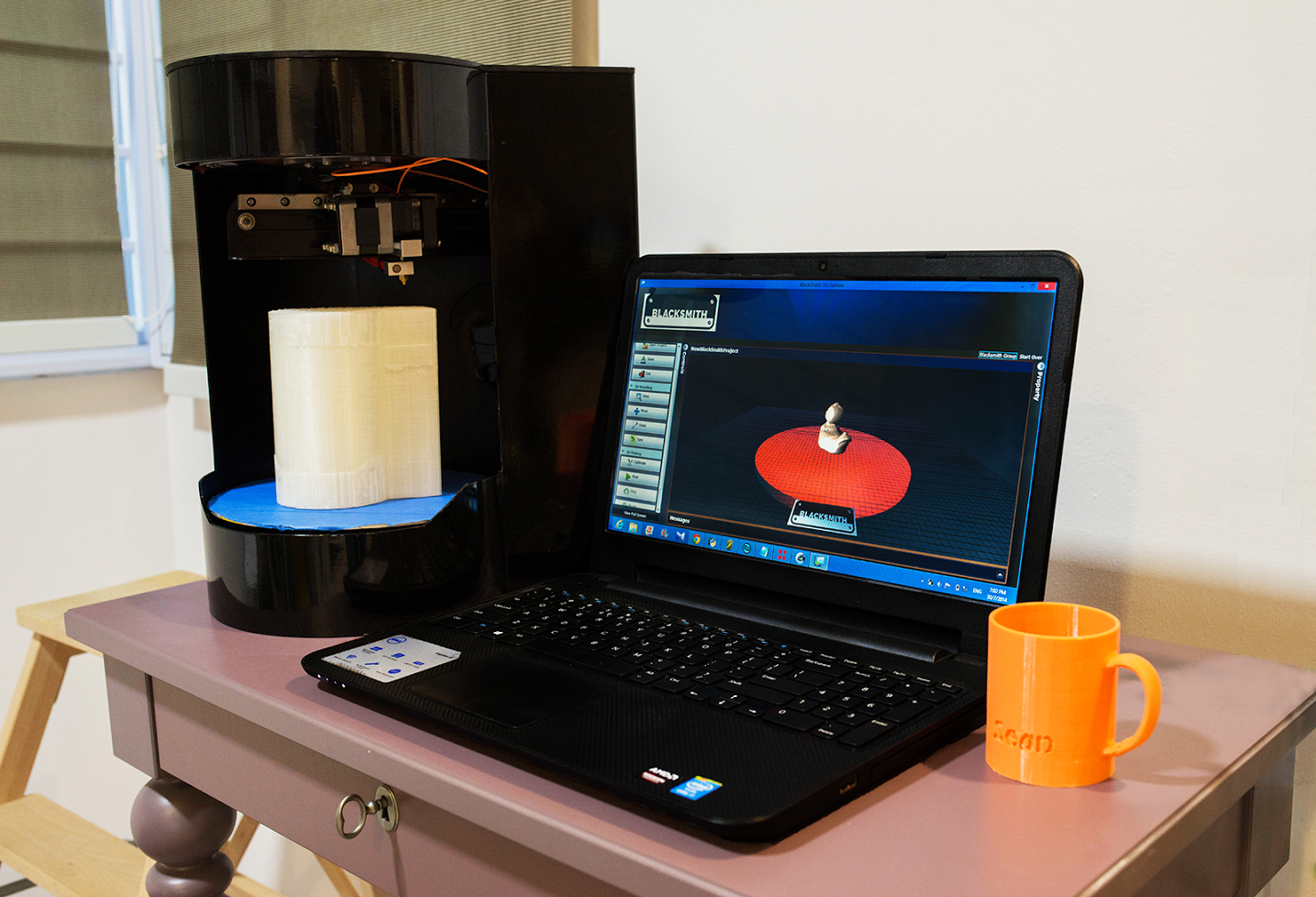

Does this approach work? Blacksmith have published some images of prints, which look pretty good but not quite perfect. We suspect they’ll be tuning their printing software over the next while to make them even better.

The build volume is decently large. Measured as a cylinder, obviously, the build volume totals 6.6L or 230mm diameter by 160mm height. For reference, the MakerBot Replicator 2’s build volume is 5.3L.

These advantages do come with a challenge: Blacksmith had to create their own software to drive the unusual mechanism, as conventional software was unfamiliar with the required movements. They include “Blacksmith Sorcerer” to do so. Even better, it works on all major operating platforms.

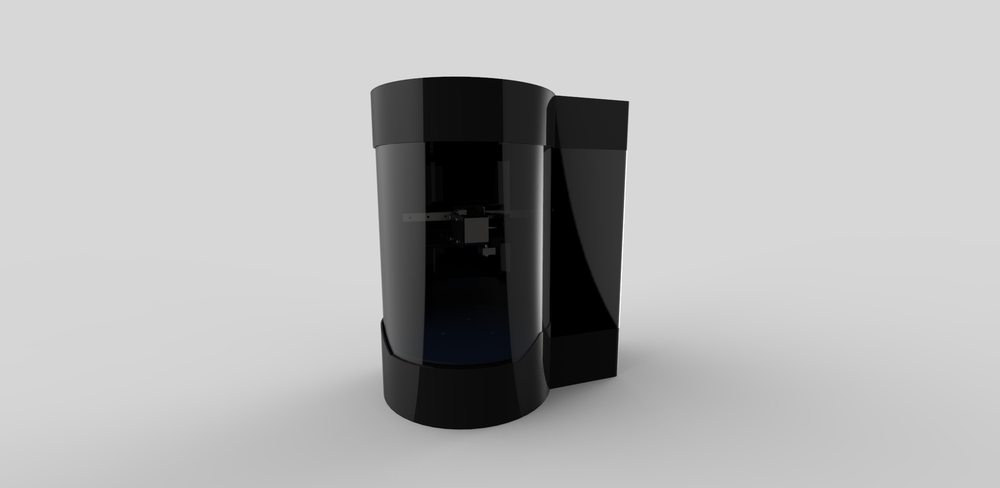

Accordingly, the exterior design of the Genesis is similarly shaped: it’s a cylinder. This alone makes the machine visually unique. But what about the rest of the device?

The machine does not have a heated platform, and thus cannot effectively print ABS plastic, but it does well with PLA and can print it at a very high layer resolution of 0.050mm. Theoretically a heated platform could be added and it might work quite well given the fully enclosed case.

What’s most interesting about the machine is that the mechanical design permits the easy addition of scanning equipment! A laser is attached to the extruder arm and can examine objects placed in the build chamber as they rotate in six minutes. The Sorcerer software then picks up the 3D capture for your use – and possible immediate replication.

It sounds good, but how much does one of these machines cost? At the moment they’ve launched an Indiegogo campaign to bring the machine to the public. Pricing is, as often occurs in such launches, variable. Early adopters can get one for USD$1,200, but the price rises over time. It’s not clear what the final retail price might be, but it will be more than USD$1,200. That’s an excellent price, particularly if you’re considering buying a printer and a scanner. Here you can get both for one price.

Via Indiegogo