Suppose you’re shopping for a personal 3D printer, like many folks seem to be doing these days. What features do you look for beyond the normal specs?

The thing is, these days there are a tremendous number of personal 3D printers available. It’s almost as if a new company markets a new machine every week. Or sooner. How can you tell them apart?

It’s become difficult, because most of these recent machines fall into the same kind of specifications window. They all seem to have an extruder or two, robust frame, smooth mechanicals, build volume of at least 150mm per side, possibly a heated bed and more. What are the features that are not so standard? Which bells and whistles could be interesting? We came up with a short list – one that we’re certain you’ll like to add something to as new features emerge.

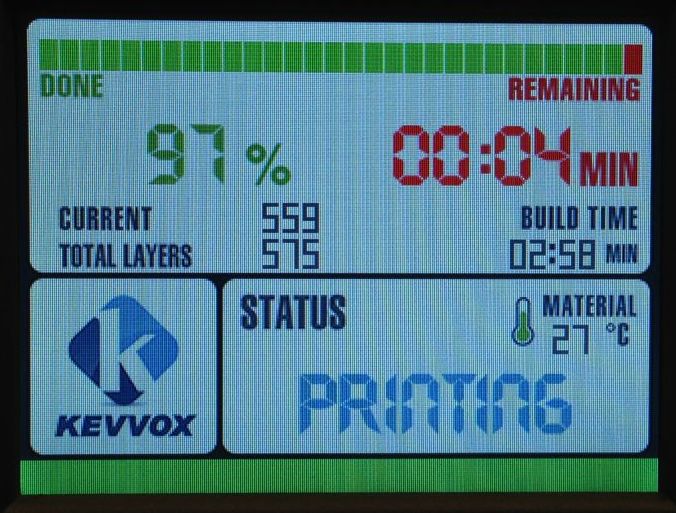

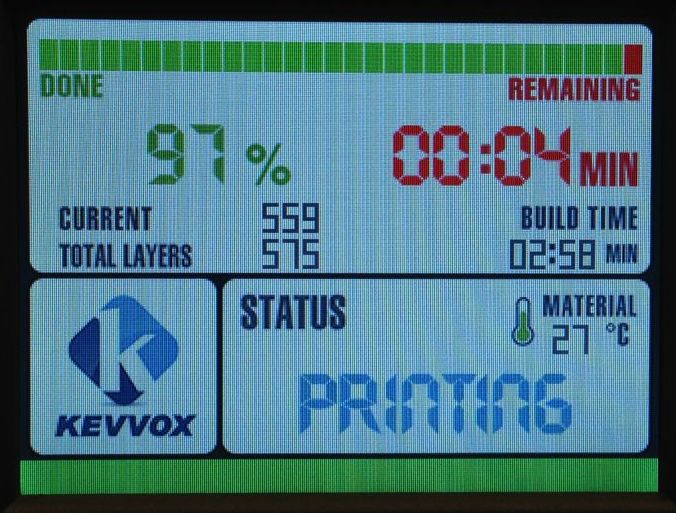

- Color Touch panel: Typical machines have an LCD status panel and a few mechanical buttons, but a feature we like to see is a software-controlled color LCD touch panel that provides clear information and controls.

- Auto calibration: Every 3D printer’s success depends utterly on being properly calibrated, but most people don’t like the extra work required to get it done. However, a rare few machines offer automated or even partially automated calibration. Not only will you save time, but you’ll also get better prints.

- Generic materials: This isn’t actually a new feature, as the first machines always used generic filament. But today, an increasing number of machines require more expensive proprietary material cartridges, making the ability to accept generic material an increasingly special feature.

- Always-Stick print surface: Sometimes it’s an add-on, but we’d like to see this feature standard on 3D printers. It’s a special plastic that provides a very reliable sticking surface for printing. Bonus: if it’s removable, you can flex them to easily crack off the prints.

- Air filter: If you can smell the plastic or resin when 3D printing, it means there are nano-particles being emitted into the local atmosphere. You’re breathing them, unless you’ve got serious air ventilation installed in your printing area. This is not always a good thing, so we’d like to see 3D printers equipped with air filters sufficient to remove them.

- Enclosed build chamber: Plastic extrusion 3D printers always work better when the temperature is consistent – and a bit higher than room temperature. While you cannot easily purchase a machine with a heated chamber from most manufacturers due to patent concerns, you can occasionally find a machine with an enclosed build chamber.

These are features you’ll occasionally see on new machines, but we’re hoping they’ll soon become defacto standards on every machine. What features would you like to see become standards?