We’re checking out a new business that supplies prosthetic fairings using 3D printing tech: Unyq.

We’ve seen this approach before, where a missing leg’s shape is reproduced by scanning the surviving leg, reversing the 3D model to duplicate the missing leg and 3D printing the result. The method involves 3D printing a “fairing”, a thin shell that’s temporarily attached to the actual mechanical prosthetic underneath.

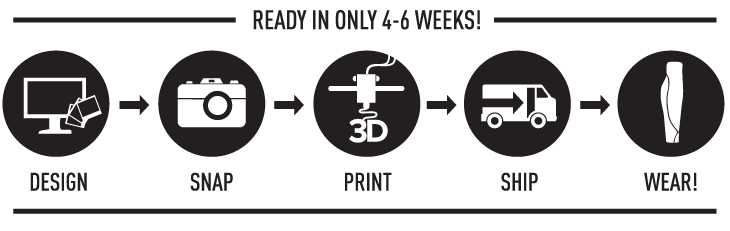

Unyq takes a full-on designer approach to the problem. They prepare a 3D model of the leg shape based on user-provided photographs, unlike previous approaches that involved complex 3D scanning equipment. With Unyq’s process, no visit to a 3D scanning studio is required. This means their business model is far more expandable – anyone, anywhere should be able to use their service.

We’re really amazed at the creativity exhibited by Unyq. One look at their shopping pages shows a wide variety of (sometimes) crazy designs that ought to get people excited. There’s no dull, human-like options here; most of the designs would fit right into the wardrobe truck of any recent science fiction movie.

Using the service is pretty straightforward; you simply select the coolest design for you, send in a selection of leg images and Unyq will prepare a 3D model for printing. They’ll complete the model by finishing it, including painting. If you happen to be a designer yourself, they’ll be happy to work with you to implement your own design. They’re now offering a way to provide fairings for double amputees, but without a good leg to scan, we presume that simply opens a window for even more creativity.

As of this writing the company offers twenty-five unique designs, ranging in price from the oddly priced USD$531.38 models to over USD$1,000.

This, we believe, is the future. A business providing custom products to everyone, powered by the technology of 3D printing.

There will be more.

Via Unyq