Have you ever wondered how 3D printing of silver or other precious metals is done? i.Materialise explains how they do it.

You might think you’d require a fancy and expensive industrial metal printing machine that laser-fuses precious metal nanoparticles together into amazing jewelry, but you’d be wrong. Sure, you can use such machines to 3D print a variety of metals, but metal 3D printing can be done in a much simpler fashion with far less expensive equipment.

i.Materialise is a 3D print service. In their vast repository of 3D models you can choose to print are multiple items of jewelry, which, of course, must be printed in metals for best effect. Like many services and hobbyists, i.Materialise uses the “lost wax” method for 3D printing of metals.

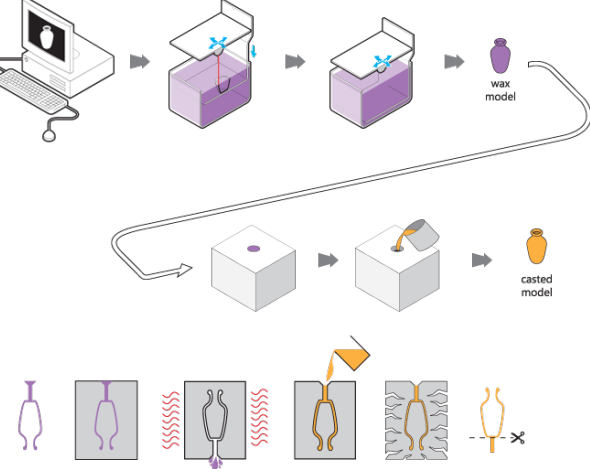

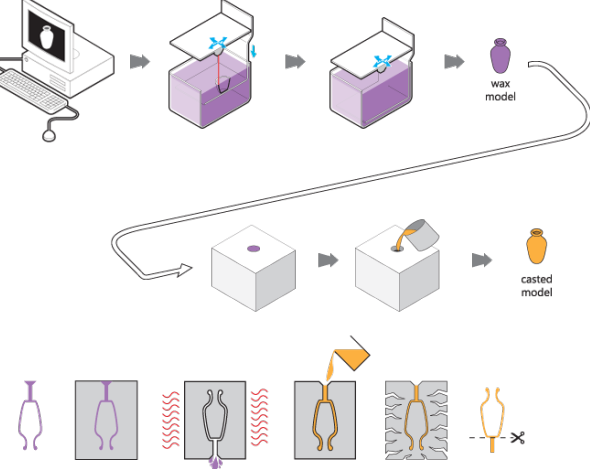

In the chart above and in their post, they explain the process. A 3D model is first produced in delicate wax at very high resolution. This fragile 3D wax print is dipped in plaster, which when solidified, forms a mold. The original wax 3D print is melted out in an oven, leaving space for molten silver (or other precious metals) to be poured in. Once cooled, the plaster mold is shattered and the metal object is removed for finishing. i.Materialise provides several finishing options, including gloss, high gloss, sandblasted and satin. Minions pop the jewelry print into polishing machines or sandblasters to achieve these effects.

You can certainly attempt this same process at home using PLA plastic instead of wax, but the resolution of your jewelry will suffer, since industrial wax 3D printers are far more accurate.

If you want beautifully finished jewelry, your best bet is to use one of the 3D print services such as i.Materialise.

Via i.Materialise