The phrase “experimental 3D printing” has been used by several manufacturers, but what does it really mean?

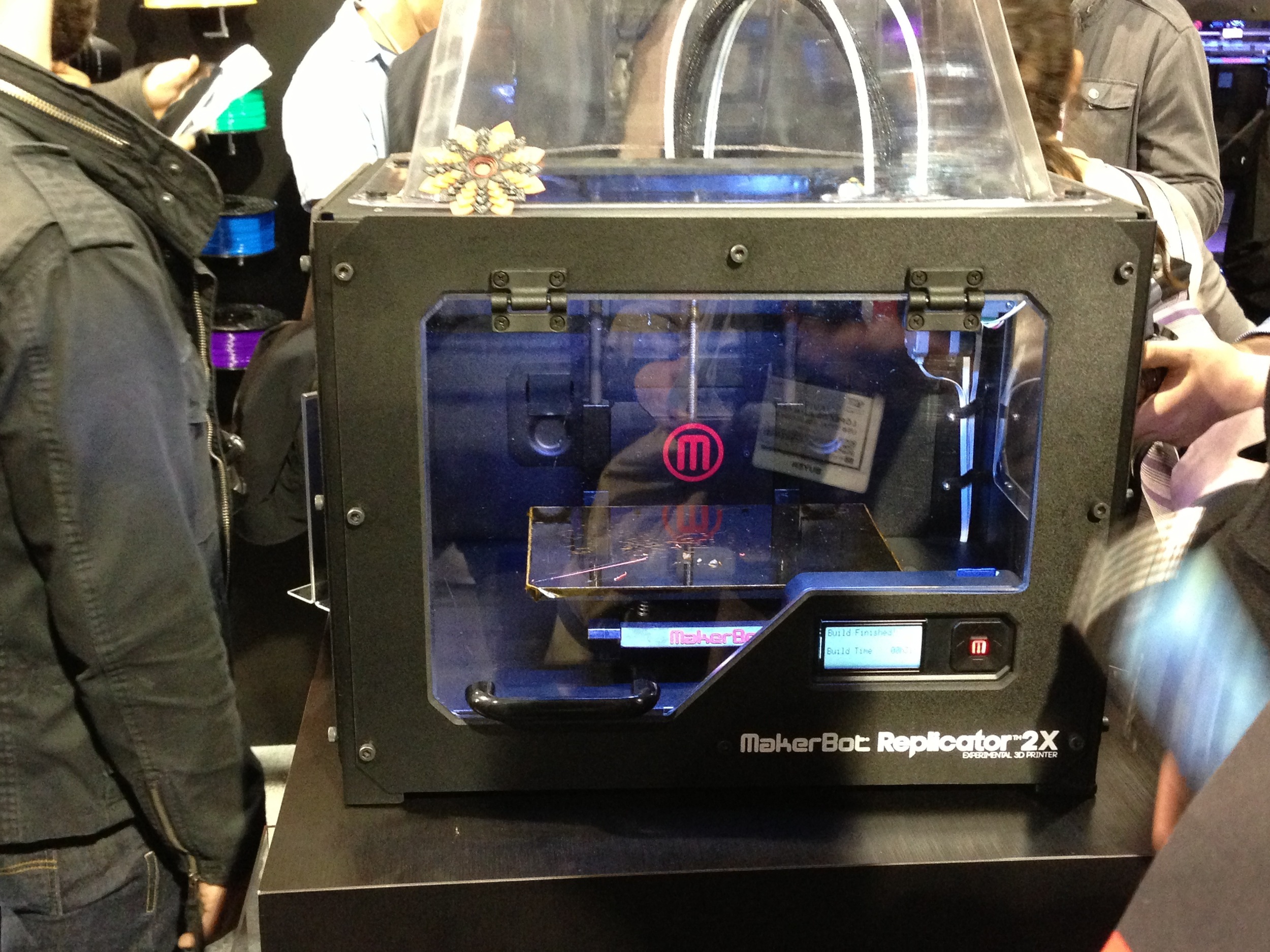

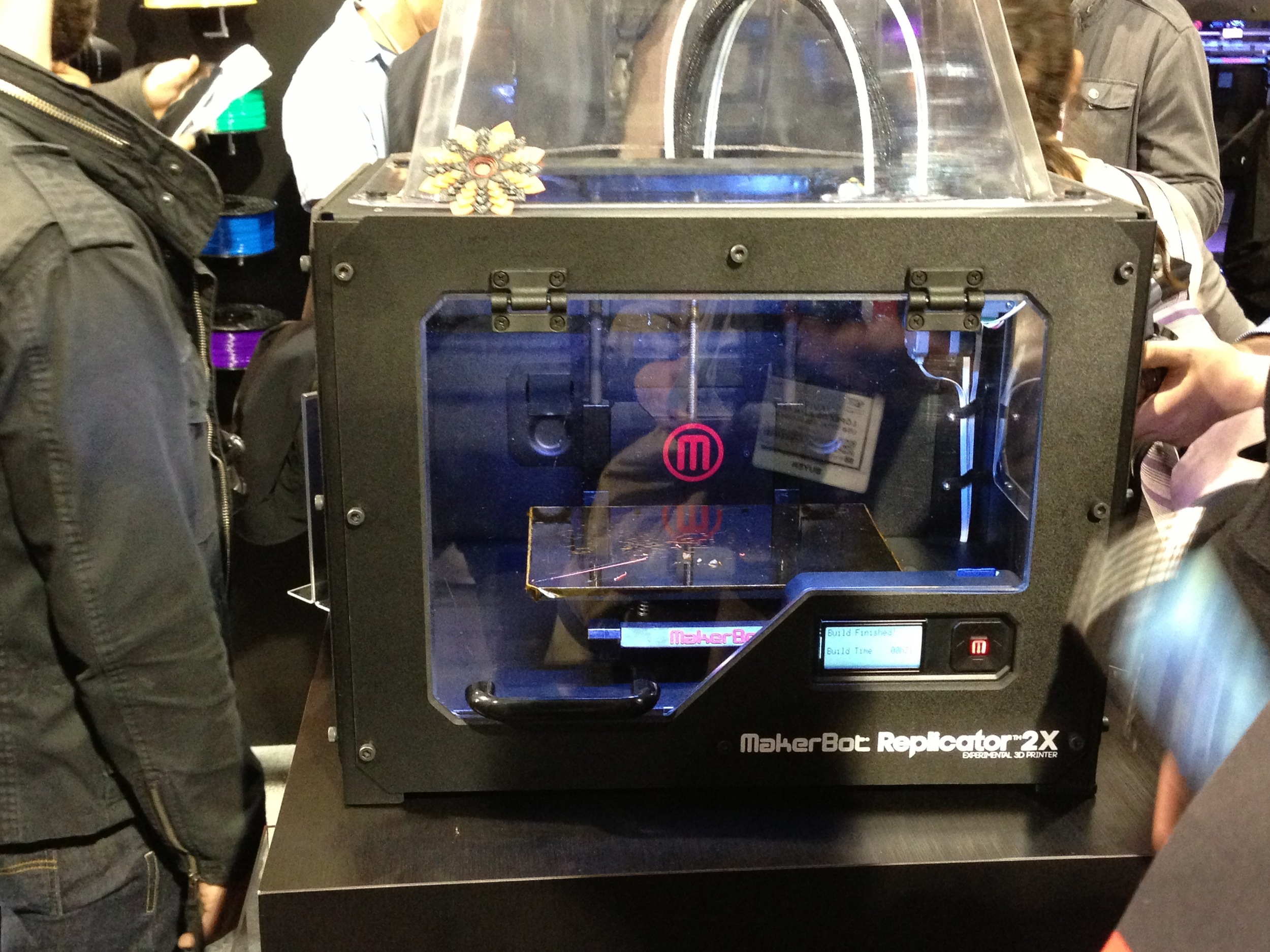

Made most famous by MakerBot when they announced their Replicator 2X “Experimental 3D Printer”. It means that the machine is capable of accepting a wide variety of 3D printing filaments that have varying requirements for temperature and other aspects. For a 3D printer to be “experimental”, we’d believe it would require at least the following features:

- An extruder capable of withstanding high temperatures, much higher than used for PLA. Often, this implies a metal extruder

- A heated bed is required to prevent warping for materials that shrink significantly when cooling

- A printing surface capable of various forms of adhesion. Different materials require different types of surfaces to stick during printing. The print surface must be able to provide them

- A printing surface that can withstand very high temperatures to match the temperature of the materials being extruded

In addition to the machine itself, you’ll find yourself behaving a bit differently if doing “experimental 3D printing”:

- You must search high and low for weird materials from strange sources

- You must install active ventilation to export the (possibly) noxious fumes from strange filaments

- You must have a lot of patience to determine successful printing parameters by trial and error when introducing a new material

It’s the opposite of consumer 3D printing: it’s an experiment that you undertake.

Meanwhile, consumer 3D printing makes strong assumptions about the materials being used and simplifies the experience.

Are you a consumer or an experimenter? Some of you may be both.