If you’ve been 3D printing you’ll be familiar with the challenge of printing overhangs. Now there’s a terrific solution that enables printing almost any shape on any 3D printer.

The solution is hidden within the free Autodesk 3D utility MeshMixer. Originally intended to, well, mix meshes, recent versions of the tool include a variety of seemingly advanced 3D model features beyond mere mesh smashing, such as sculpting, stamping patterns, and analysis.

The analysis is quite interesting, as it can measure distances and angles between points, compute volume and surface area, determine the exact center of mass, provide a heat map of stress points (in the image above), and calculate overhangs.

But not only can it identify overhangs, but it can also generate custom support structures to deal with them. You have complete control over the nature of the supports through a dozen or so separate parameter controls. You can also manually add or subtract supports. You can make them thicker or thinner. We found the defaults to be usable in many situations, so there’s often not much to do. Also, they look very cool with their Borg-like snakey appearance.

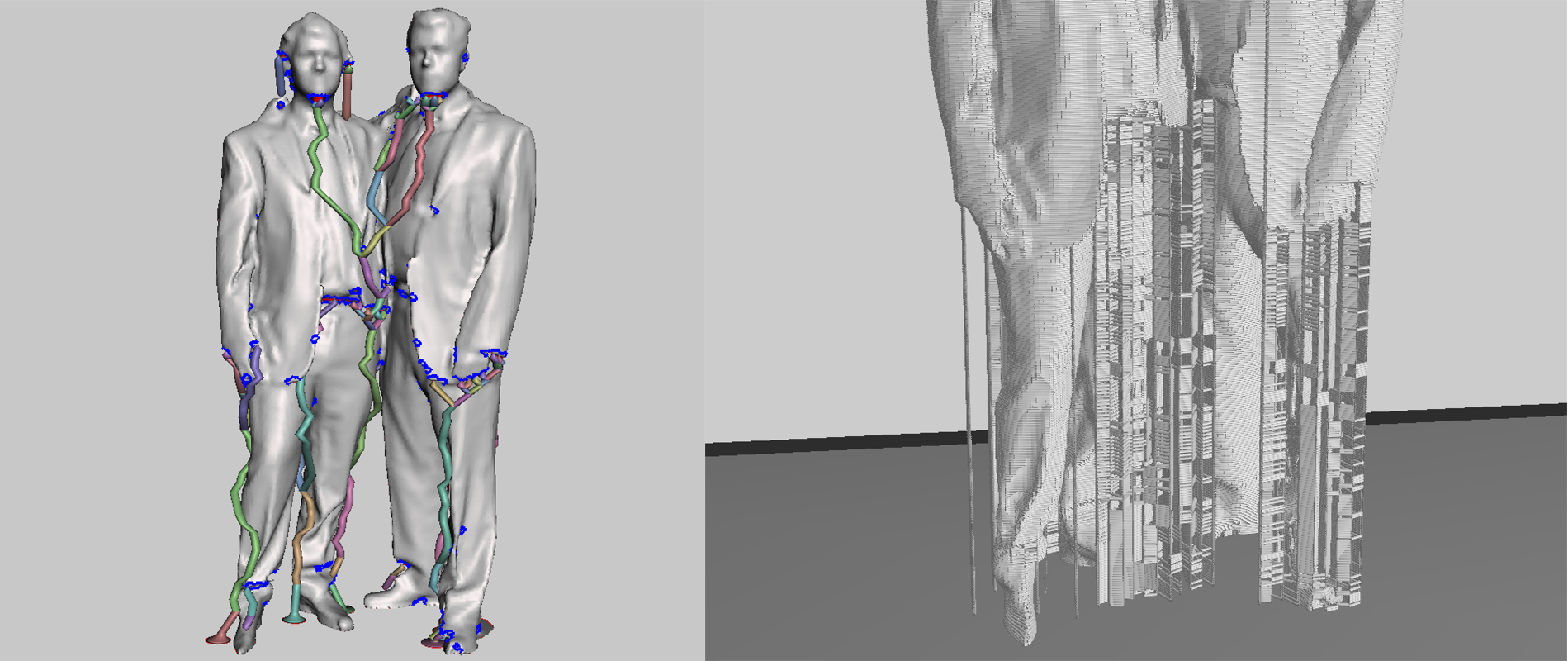

The results are startling. In the image above, these dudes have far less support generated by MeshMixer (left image) than MakerWare (right image). Not only that, the MeshMixer supports are both easier to print as they have proper bases and easier to remove. The MeshMixer supports also use far less material. Even for totally pathological objects, such as the image at the top, MeshMixer supports work well.

It’s an extra step in your workflow for sure; you basically make a new 3D model that includes the generated supports and then just print that. Pull the supports off with some pilers and you’re done.

We’re thinking this is a very significant capability. It means that owners of single extruder 3D printers now have a really good option for printing complex geometries. Typically dual extruders were used to print support structures in a different material, but the results with MeshMixer are almost as good. The only situation we can imagine this not working is if the supports must be embedded within an object.

There’s one other major bonus: because you can more easily use supports, it would be possible to print your models at peculiar orientations to take full advantage of your build volume. In other words, the maximum dimension of your prints could be the diagonal between opposing corners of the build volume. You’d use a bit more support material, but far less than with typical slicers.

For those of you who have been afraid to try printing unusual shapes or extra-large prints, now is the time to try MeshMixer supports to enable your 3D printer to take on anything.

Via MeshMixer