We’re checking out a new venture that uses 3D printing to create custom made orthotics: Sols.

A great many people require orthotics, which are simply replacement inserts for your shoes that provide additional strength and motion control. For some people orthotics are essential. The catch is that everyone’s feet are different. In fact, you’ll likely find your left is actually different from the right!

To date the process for orthotics has been rudimentary. You either buy an orthotic that is a standard size (and by definition won’t fit perfectly) or you go through a traditional manufacturing process whereby your foot’s shape is “captured” through some type of analog method (like a mold) and then hand made at great expense.

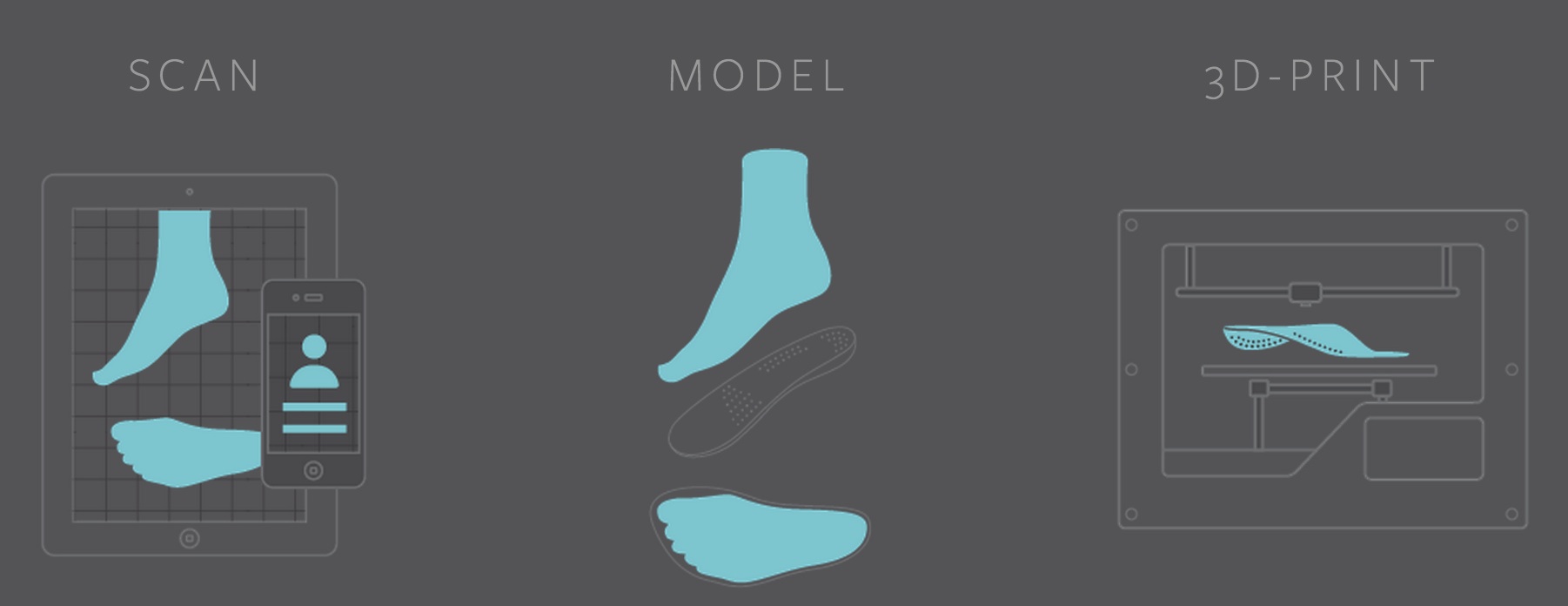

New York-based Sols hopes to break through that barrier by creating a different workflow. You will provide a ten second video of your unsupported foot and their proprietary software will derive the precise orthotic shape automatically. They’ll 3D print the orthotic to the correct size in strong nylon material and send it to you within two weeks.

As far as we can gather, their market is not consumers, but rather podiatrists and other professionals who normally provide orthotics. Nevertheless, we see this as the perfect application of 3D printing: mass producing a product that should ONLY be made to custom fit each person.

Via Sols