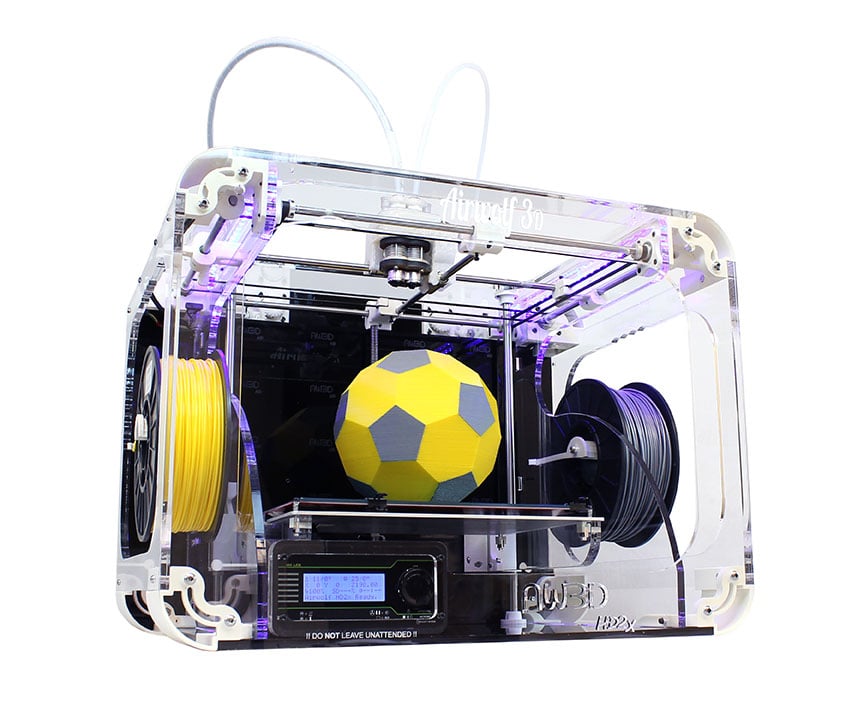

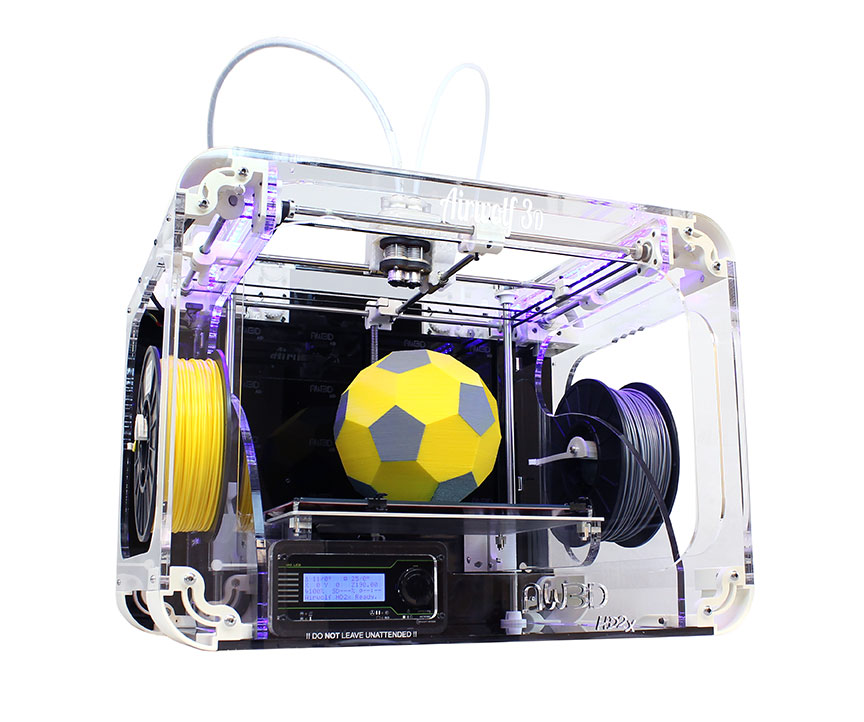

Airwolf just announced a new dual hot end 3D printer, which solves a problem experienced by most dual extrusion machines.

The problem by the new Airwolf AW3D HD2x is alignment. Typically two extruders are mounted on a carriage and they alternately extrude material during a print. These extruders must be very precisely aligned with each other, or else extruder 1’s material will be slightly offset from extruder 2’s. The alignment process can be tricky, as you may have to precisely measure the distance between tips in up to three dimensions. These measurements are then used by the printer’s firmware to adjust movements to account for the misalignment.

Usually these measurements are not precise, leading to problematic prints. You’ll see gaps or blobs when extrusions from the two tips don’t quite meet or overlap.

Now Airwolf claims to have solved the issue by building a single component holding both extruders. They say:

The secret lies in the proprietary, patent-pending JRx print heads, each powered by its own stepper motor. Unlike other 3D printers, the two hot ends are manufactured as a single piece. This fixed relationship eliminates x and y axis alignment problems because there is no slippage; the heads are always in frame. As such, the machine’s dual head spatial calibration is fixed in the firmware rather than in the user interface.

Even better, the JRx hot end series is capable of printing not only PLA, ABS and PET materials, but also high-temperature materials like Polycarbonate and Nylon.

The HD2x includes a very generous build volume of 279 x 203 x 305mm, a layer size of 0.06mm and sports nylon gears for extra wear and tear. Thus, your new HD2x is a very capable 3D printer, indeed.

The unit is assembled and will sell for USD$3,995.

Via Airwolf