RSscan and Materialise have teamed up to create RSPrint, a new joint venture that is capable of scanning human feet and 3D printing custom insoles that precisely fit the scanned human.

RSscan “special “Footscan®” hardware and software for dynamic pressure measurements in science, topsport, clinical markets (orthotics, podology), leisure and much more”, while Materialise is a well-known commercial 3D print service. It’s an obvious partnership: RSscan produces the digital foot models and Materialise brings them to life.

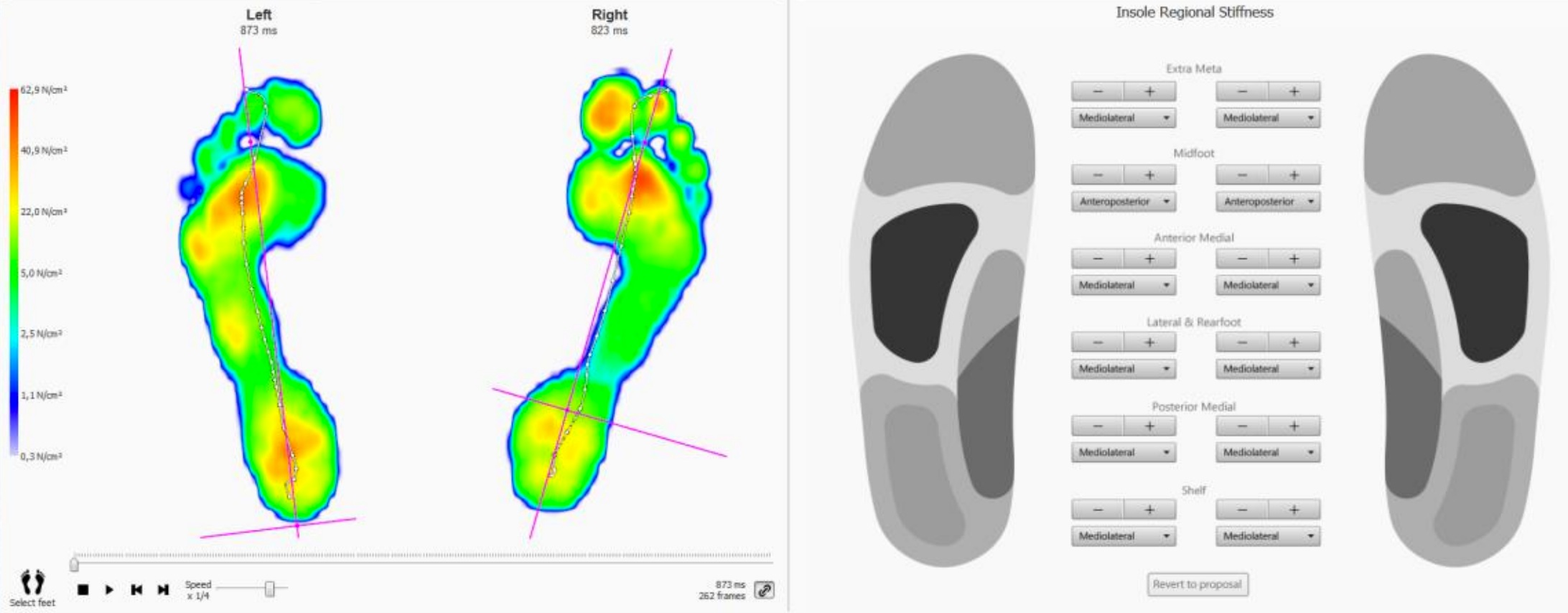

The process is straightforward: a human subject stands (barefoot, obviously) on the foot scanner and pressure sensors map the foot. Software interprets the map and produces a 3D model of insoles that complement the scanned foot. Materialise receives the 3D model and prints it for delivery.

We’re interested in this because it brings 3D printing a bit closer to the dream of individually replicated clothing. We’re not 3D printing shoes here – but we are 3D printing part of a shoe, in fact the most important and personal part of the shoe. A natural extension of this capability would be to add on uppers and lowers of various styles and sizes that match the insole. Then we’d have true, personal shoe printing.

Via Materialise