IBM announced the discovery of two new classes of polymers, the first discovered in decades. We’re wondering if they have any applicability to 3D printing.

The two polymers were “discovered” in a very different way from traditional approaches. Instead of time-consuming trial and error, as has been done for over 100 years, IBM used their considerable number-crunching abilities and lab work to “model new polymer forming reactions”. In other words, they used software to dramatically speed up the search for the new polymers.

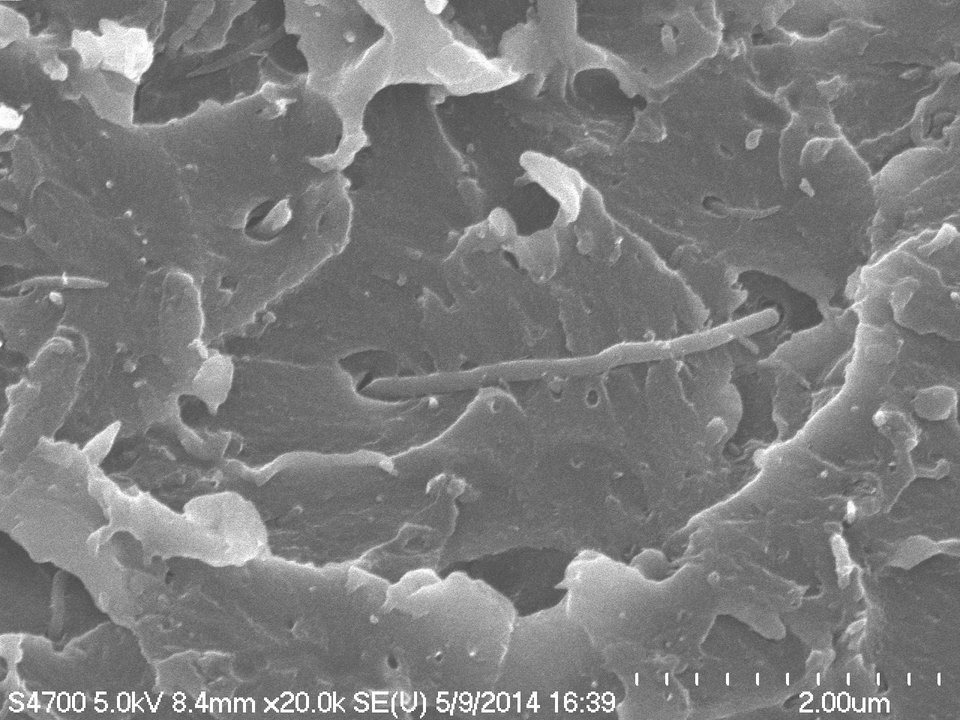

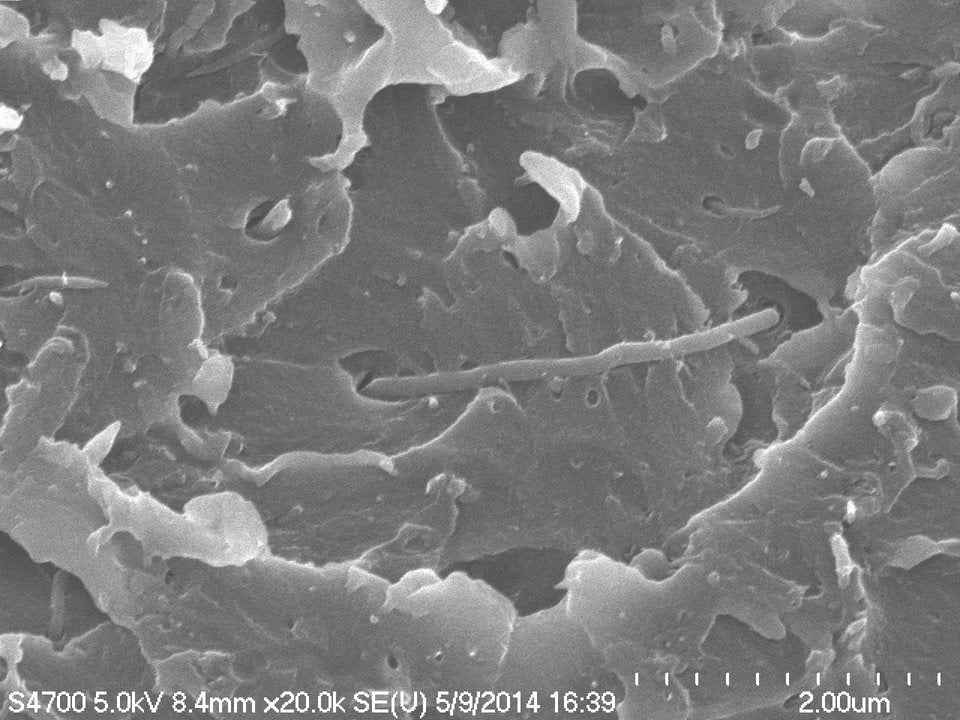

The two materials have vastly different properties. “Titan” is a very hard material that is “stronger than bone and fiberboard”, but is as brittle as glass. The other material, “Hydro”, is gel-like and has the curious property of self-healing. If you place two samples beside each other, “the chemical bonds are reformed between the pieces making it a single unit again within seconds”.

While we’re quite certain Titan and Hydro won’t be commercially available for a while, we do wonder whether they could be used for 3D printing if formed into appropriate filaments. Hydro likely cannot as it is a gel, but perhaps it could be extruded with syringe-based 3D printers. It’s also possible Hydro could be mixed with other polymers to create extrudable compounds that self-heal.

Titan is also interesting: at 250C it becomes “incredibly strong”. We’re not certain how this may be used in 3D printing. One concept could be to 3D print an object, then bake it at 250C to make it rigid.

Some may believe extrusion-based 3D printing is mature. The mechanical technology may be so, but the materials used in such machines are not. If IBM keeps running their discovery system, we may see many new extrudable materials that may change 3D printing possibilities.