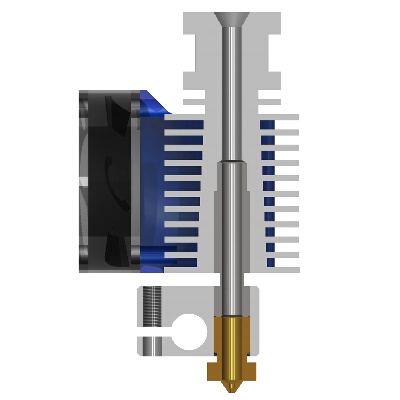

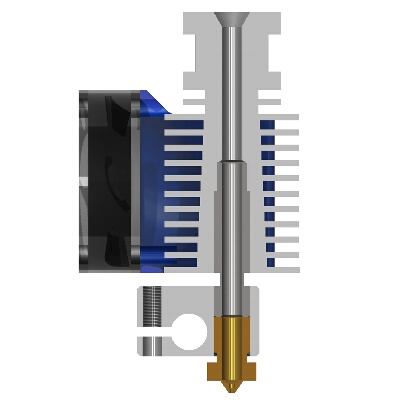

E3D released the latest version of their high-performance hotend for extrusion-based 3D printers.

You may think that one extruder is pretty much the same as the other, but it’s just not true. The act of extruding melted plastic is one fraught with critical balances of temperature, speed, chemistry and more. By carefully tuning the hotend it’s possible to enhance your 3D print results with increased resolution, fewer blobs, reduced failure rates, etc.

E3D’s new design includes some interesting features, including reduced weight, which should enable faster printing, more efficient cooling with a custom shroud and re-tuned geometry for more reliable use with Bowden extruders.

The most interesting new feature is reliable support for flexible filaments, which are notoriously difficult to 3D print on many machines. While you’ll still have to print quite slowly, the E3D hotend improves the experience. They say:

The amount of difference this makes when printing 1.75mm flexible filaments is staggering, we went from slow prints at 5-10mm/s that would stop feeding due to buckling with terrible oozing and retract performance to printing at 20-30mm/s with perfect reliability and retractions that were actually very effective at combatting ooze.

The E3Dv6 is available in several models ranging from £43-48 (USD$72-80).

Via E3D