Researchers at the Australian National University have created an inexpensive 3D printed lens that can attach to a smartphone and detect some skin diseases.

Traditionally, lenses are manufactured by using a grinding and polishing method, or through the pouring of gel materials into pre-fabricated molds. While these methods have been very effective, they’re also quite complex and expensive.

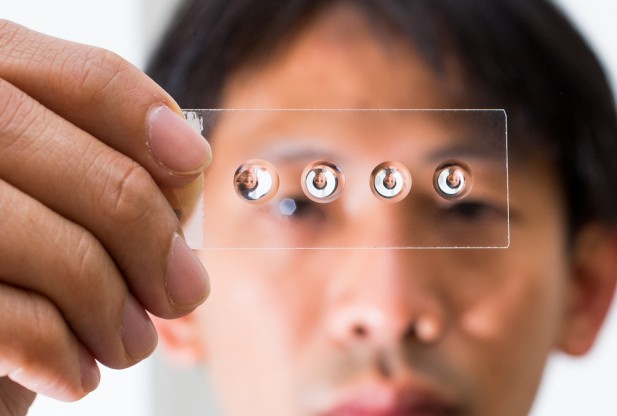

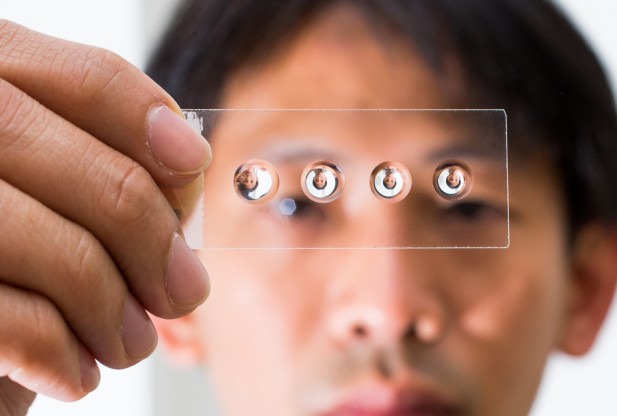

To bypass this costly construction ANU researchers began exploring how clear liquids can bend light and act as a lens when stabilized. Remarkably, through their research the ANU team developed a completely new method for manufacturing lenses that requires only an oven, a silicon polymer and a glass slide.

In a modest tone, lead researcher Dr. Steve Lee stated, “What I did was to systematically fine-tune the curvature that’s formed by a simple droplet with the help of gravity, and without any molds.”

Read more at ENGINEERING.com