Australian engineer Daniel Brown has been experimenting with overhangs, the bane of 3D printer operators worldwide. It looks like he’s managed to overcome them.

But first, what’s the deal with overhangs? They are geometric shapes in a 3D model that have no material underneath them, making layer-based 3D printing challenging. Most personal 3D printers must print “support” structures underneath to prevent the overhangs from immediately collapsing during printing.

Some overhangs are tolerable, though. You can often safely 3D print overhangs with as much as a 45 degree angle overhang without issue. More than that and you’re asking for trouble, which in this case means droopy filament strands.

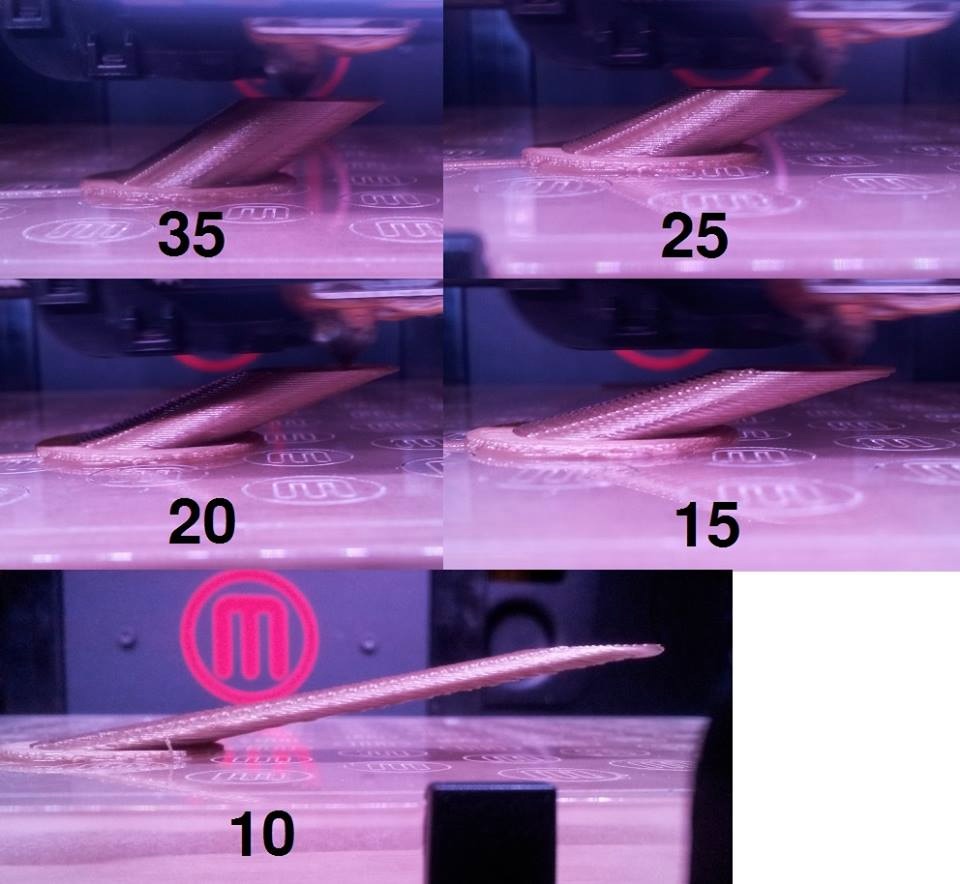

Brown did an experiment to see how much overhang is really possible on a MakerBot Replicator. By progressively increasing the angle one could see where a failure occurs. However, it appears from the images above that he was able to tip the column to a mere ten degrees from horizontal.

The result is not quite perfect, as you can see some very slight blurbs on the bottom of the ten-degree column. But the result is very impressive nonetheless.

We suspect this extreme success has something to do with the overall geometry of the particular model being printed. Brown says:

What I think allowed this actually was the cross section of the part, that is a circular column, slanted therefore the maximum overhang only exists at the furthest point of the structure while it seemed to be held in place by the sides which comparatively we not overhanging at all.

Regardless of how it was accomplished, we’re definitely taking a much more aggressive stance on overhang angles from now on.

Via Reddit