Earlier last week HP CEO Meg Whitman revealed that HP would have some kind of announcement regarding 3D printing this June. We take a look at a possible technology they may use.

Whitman hinted at much more rapid print speeds, while also increasing accuracy. This is not really possible with existing technologies, so what might they be doing instead? One of the technologies being used in some of HP’s higher-end 2D printing devices is Memjet Waterfall Printhead Technology.

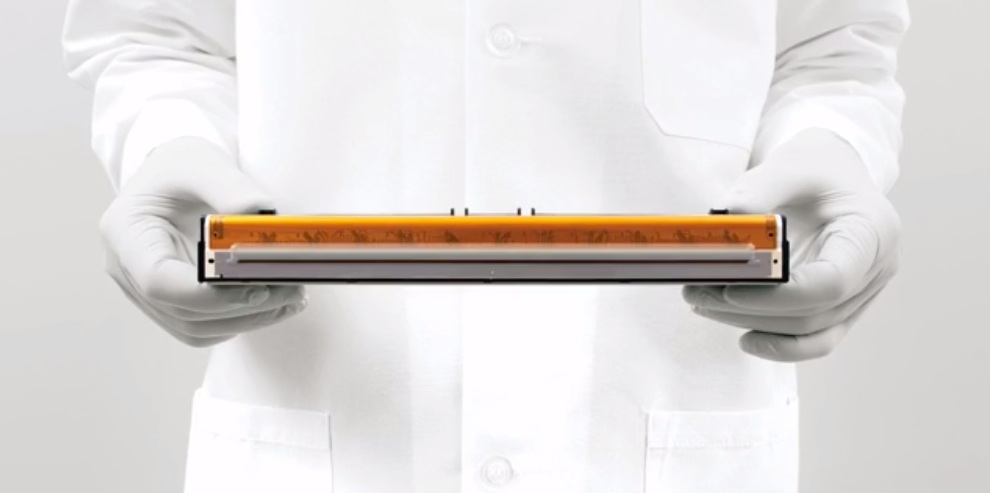

Made by Memjet and embedded into HP printers, the printhead is capable of printing ink 223mm wide at a rate of 305mm per second. Yes, that’s per SECOND. In other words, it can put out a new page in less than a second. The ink “falls” from 70,400 microjets in the printhead onto the paper streaming by below, yielding 1600dpi resolution. Watch the video here to see exactly how fast this device can deliver ink:

But that’s paper, not 3D printing.

Imagine, though, if this were adapted to 3D printing. We’d foresee a memjet printhead moving very rapidly across a powder bed, selectively dropping “binder” to form solid layers. Perhaps the printhead (or multiple heads) could be flying by on a wraparound conveyer belt for high speed operation. Another approach could be to stack a bunch of memjet printheads together to minimize required movements.

If the printhead(s) could move as fast as the paper moves in 2D printing (which is unlikely), you would see a layer produced in less than a second, stupendously faster than today’s 3D printing. However, it’s more likely they will be slower. Even at two seconds per layer, a 1000-layer print would take a little more than half an hour. That’s pretty fast. Watch the video again and imagine the 2D sheets emerging are actually solid layers of a 3D print.

Is this really what they’re doing? We have no idea – but the technology is there and they’ve had several years in secret labs to figure out a method that works.