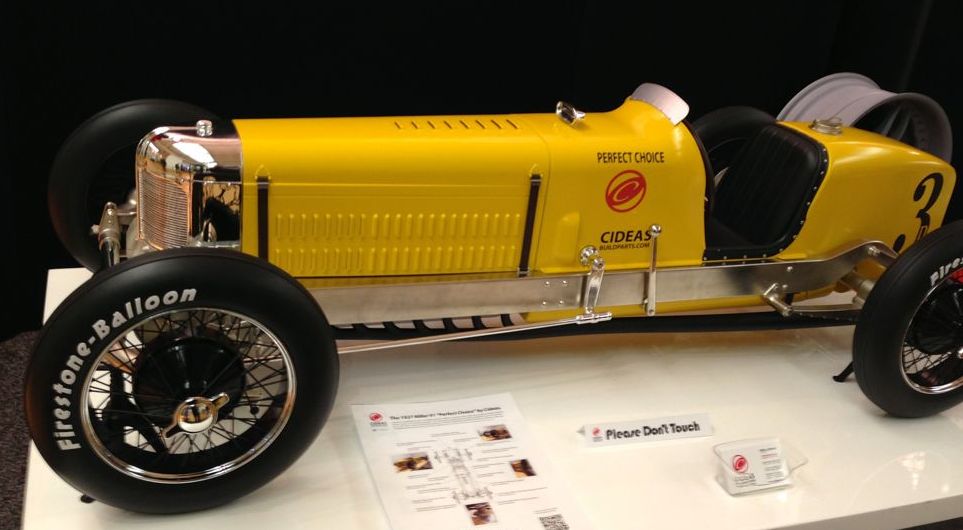

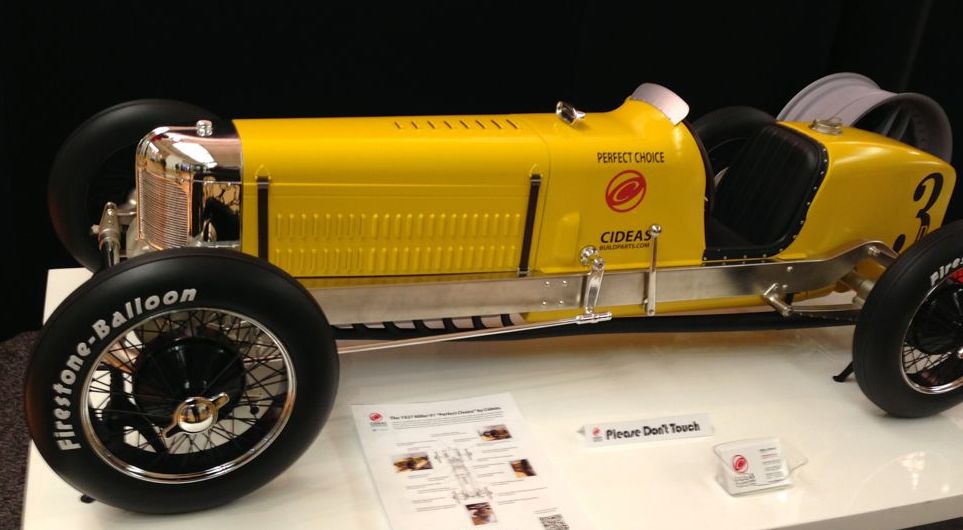

We managed to get a very close look at an incredible 3D print. It’s so good you’d never know how it was made.

The 1927 Miller 91 replica was built by CIDEAS, or by their other name, BuildParts.com, a commercial 3D print service. It’s a 40% scale model of the original and you’d swear it was a real vehicle – until you ask how it was made.

Most of the vehicle was in fact 3D printed. But what a print!

- 580 hours of 3D printing

- 740 cubic inches of print material

- 130 hours of post-processing

The company wanted to illustrate their capabilities in a variety of 3D print technologies, and did so by involving no less than four different 3D print methods:

- SLA White Body, Wire wheels, Wheel rings & Spinners, Hood, Gauge & intake

- FDM ABS Exhaust, Tires, Frame and Underbelly, Steering wheel, Grill & Transmission

- SLS Nylon Shifter & pedals, Tie Rods & Steering linkage, Gas cap

- SLS Glass Filled Nylon Structural brace

- PolyJet Tire letters, Engine straps, Seat cushion

Finishing included nickel-plating some of the pieces, which are visually indistinguishable from real metal parts.

If only we could do this at home. Maybe in the future this could happen, but for now you’ll have to use 3D print services such as Buildparts.

Via Buildparts