Solidsmack reports on a fascinating attempt to 3D print an entire working clockwork motor in a single print operation. Did it work?

It did. After many hours of 3D design, six hours of 3D printing on a Stratasys Mojo and finally another six hours in the washer, Danny Tasmakis was able to successfully produce a working clockwork motor.

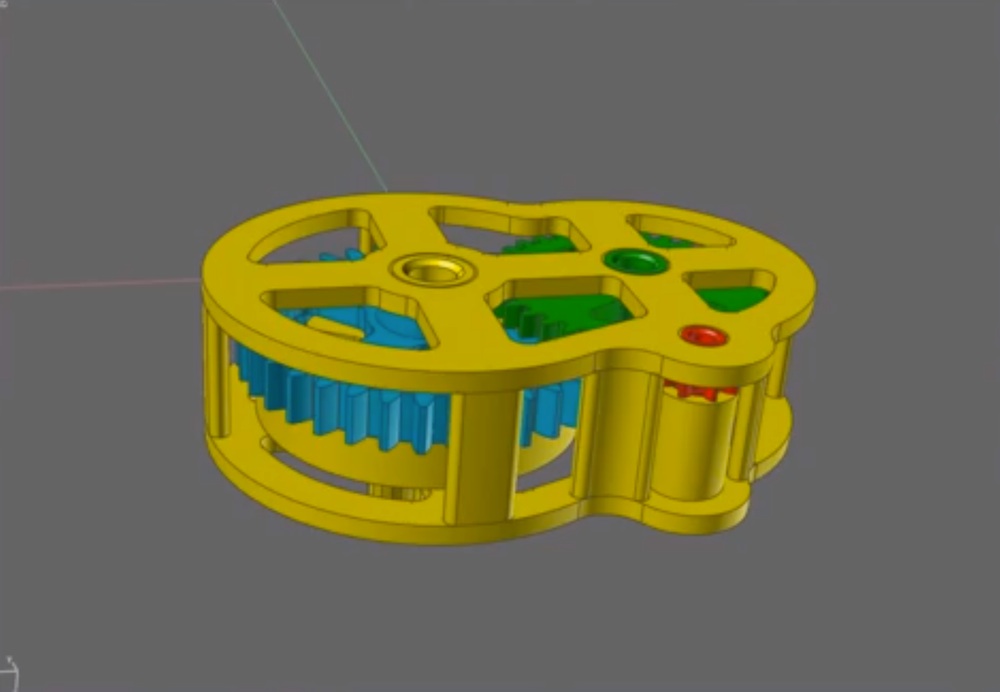

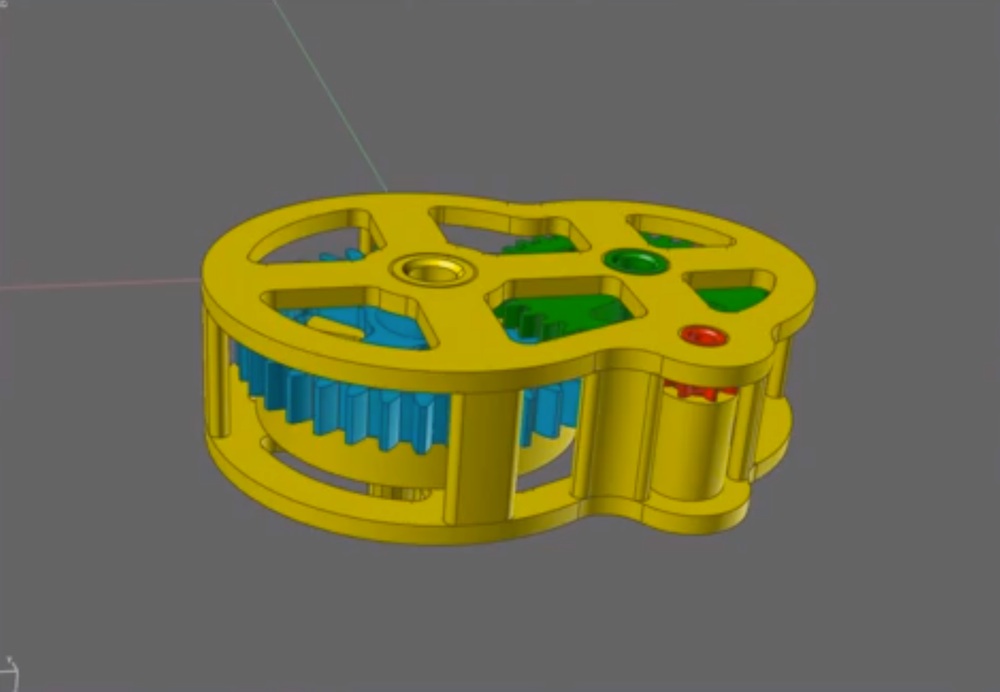

It’s a windup mechanism that uses a spiral spring for power storage. It’s definitely not powerful, but it was done to illustrate the possibilities of 3D printing with dissolvable support structures.

In this image, the completed print emerges from the Mojo. It appears to be a solid mass, but in fact the ABS plastic of the mechanism is more or less surrounded by tons of support material. This special plastic is dissolvable in Stratasys’ wash tank, freeing up the spaces between the individual parts of the mechanism. Once gone, the parts move freely as originally designed.

In theory any 3D printer equipped with dual extruders could accomplish the same feat by using a dissolvable plastic as support. Typically on personal 3D printers that would be PVA plastic.

One other thing you’ll need is CAD software capable of designing assemblies of moving parts, which is not typically a feature of lower-end tools.

That and a really good idea for a mechanism.

Via Solidsmack