Many years ago we wrote a brief story on Contour Crafting, who, if you don’t know, are developing the technologies necessary to 3D print entire buildings in concrete. The idea is to erect a “portable” 3D printer gantry around a home-building site and have the device extrude the walls of the building.

This approach would provide a number of interesting advantages:

- Precision building guaranteed to match the intended 3D model

- Quality control as the majority of the build is done by machine, not by potentially unreliable humans

- Variation in design; no more rows of identical houses as each 3D house model could be uniquely customized

- Speed of building would be tremendously increased; Contour Crafting’s goal is to print a home in 24 hours

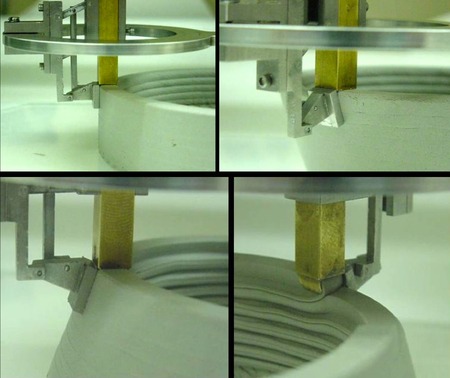

As you might imagine, there are great challenges in developing the necessary technology. However, Contour Crafting, led by Professor Behrokh Khoshnevis of USC is doing so. They’ve been able to develop techniques for extruding concrete using computer-controlled trowels attached to the extrusion head, which, as you can see above, are able to successfully 3D print concrete structures. These structures have demonstrated enormous strength, being able to withstand 10,000psi, whereas typical conventional builds can only handle 3,000psi.

In a recent interview with Microsoft, Professor Khoshnevis says:

At the dawn of the 21st century [slums] are the condition of shelter for nearly one billion people in our world. These buildings are breeding grounds for disease a problem of conventional construction which is slow, labour intensive and inefficient. Your shoes, your clothes, home appliances, your car. The only thing that is still built by hand are these buildings.

The team at Contour Crafting and the Center for Rapid Automated Fabrication Technologies, CRAFT, have accumulated a tremendous amount of research into all aspects of the problem. Will they succeed? We aren’t certain they will, as their concept has been underway for well over seven years; It may be that the concept of on-site 3D printed buildings is not feasible. Others are working on an alternative approach involves 3D printing building components in a central factory, where they would be shipped to the building site.

Via Contour Crafting and Microsoft