Those new to personal 3D printing may still glow from the thrill of creating objects simply by pushing the “print” button. It is always amazing to see objects appear from nothing and then hold them in your hand.

But is this the end of it? Will you simply print plastic items?

Not necessarily. Newbies may think of their 3D printer as a black box that produces objects, which is of course true, but there is much more you can do by thinking of 3D printing in a different way.

Think of 3D printing as a type of manufacturing process. It’s one of MANY ways you can build things. By having a 3D printer you now have access to another manufacturing process, which can be combined with other processes to enable the making of different and more complex items.

The simplest form of additional manufacturing process would be finishing. Your 3D printed objects can be sanded, painted or smoothed.

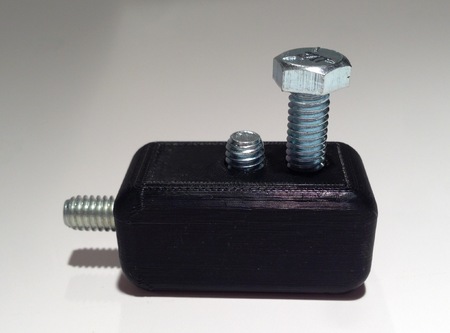

Assembly: 3D printed parts can be glued together, or even snap-fit if you’ve designed them appropriately. Parts may be drilled and bolted together.

If you have access to other making machines, such as CNC wood cutters or laser cutters, you can make pieces that can be combined with 3D printed parts to create larger structures. 3D printed joints, for example, can be used to link laser-cut beams into a housing in ways not usually possible.

When you’re tired of printing plastic pieces alone, consider combining 3D printing with other manufacturing techniques.

You’ll discover a world of possibilities.