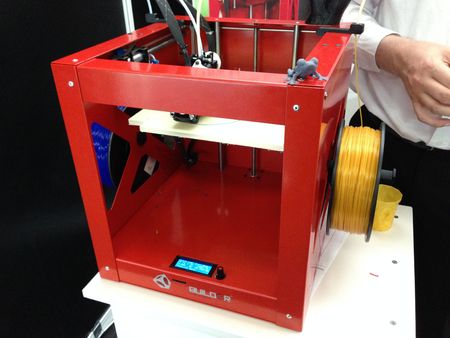

At the 2013 3D Printshow we stopped by the Code-p west BV booth, who produce the Builder personal 3D printer. These folks produce a typical personal 3D printer, but as we talked with their spokesman, something very interesting was revealed.

At first, their machine appears much like many other personal 3D printers: a cubic frame with XYZ axes allowing an extruder to move about, gradually extruding malleable plastic into shapes. But then we noticed it.

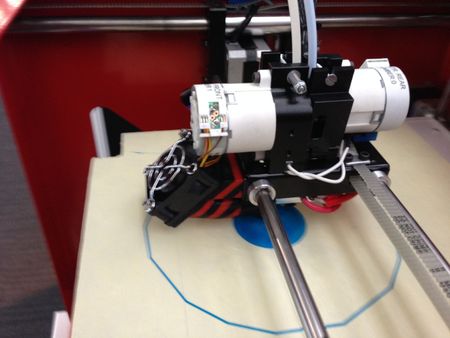

There were two filaments entering the extruder. Not one. TWO.

We immediately asked more about this feature. It seems that they have a single heat chamber, where both filaments are softened for printing. However, only the filament that is being pushed comes out of the nozzle.

But what if BOTH extruder motors are going at the same time?

Then the filaments are mixed. Mixed colors!

When we regained consciousness, the spokesman explained that the feature cannot truly do much yet, because they do not have software to drive color mixing. Indeed, the state of color management for 3D printers is truly awful, at least at the consumer end these days.

Perhaps you’d like to experiment with this new color mixing feature? If so, you’ll have to spend £1325 (USD$2100). For that you’ll receive a good quality PLA-only 3D printer, capable of 0.1mm resolution.

You’ll also need a pile of colored filament, of course.

Via Builder

Yeah, this was done by RichRap over a year ago with 3 extruders. It does not work, because the plastics are not mixed, they just comes out next to each other, so if you run red and blue together, the print does not come out purple, rather is looks red from one side and blue from another side.

http://richrap.blogspot.dk/2012/08/3-way-quick-fit-extruder-and-colour.html

Yeah, this was done by RichRap over a year ago with 3 extruders. It does not work, because the plastics are not mixed, they just comes out next to each other, so if you run red and blue together, the print does not come out purple, rather is looks red from one side and blue from another side.

http://richrap.blogspot.dk/2012/08/3-way-quick-fit-extruder-and-colour.html

Mooi Sven!

Mooi Sven!

Very nice to see this article about the dual extruder I've invented at Code-P West. I have to say, the dual extrusion prints get out way better than with two nozzles. This is mainly because there's no need for calibration of the dual nozzle alignment (since there's only one nozzle) or a dripping second nozzle.

Mixed colors are only possible with 5D firmware, and a lot of experience with 3d Printing…

Follow @umakeprinting on twitter to see more updates on prints, made with the next gen dual extruder.

Very nice to see this article about the dual extruder I've invented at Code-P West. I have to say, the dual extrusion prints get out way better than with two nozzles. This is mainly because there's no need for calibration of the dual nozzle alignment (since there's only one nozzle) or a dripping second nozzle.

Mixed colors are only possible with 5D firmware, and a lot of experience with 3d Printing…

Follow @umakeprinting on twitter to see more updates on prints, made with the next gen dual extruder.