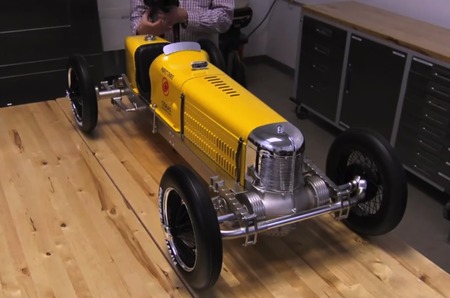

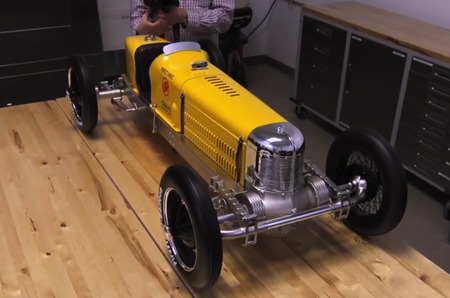

It’s one thing to print simple items with your 3D printer, like a coat hook or clamp, but some people take the power of the technology to the limit. The folks at CIDEAS, a commercial 3D print service bureau, pulled out all the stops to produce a small scale replica of a 1927 Miller 91 racing car – entirely from 3D printed parts. The result, as you see above, is incredible.

This is not a project you’d attempt at home. The car’s components were produced with multiple commercial 3D printers that, of course, were available at CIDEAS. The different car parts required different physical characteristics, so they employed these technologies:

- Stratasys’ FDM (melted plastic extrusion)

- Stratasys’ Polyjet (liquid extrusion)

- 3D Systems’ SLS (laser fused nylon powder)

- 3D Systems’ SLA (laser cured UV-sensitive resin)

The model also required custom painting and a whole lot of sanding. Never forget that finishing is an important part of 3D printing.

They’ve documented the entire process of their adventure producing this incredible model in a video. In it you’ll see each of the different 3D printing processes in action, as well as the finishing and assembly steps.

The 1927 vehicle model was done as a promotional item for CIDEAS to exhibit at trade shows to demonstrate what’s possible. They say that many people don’t understand that the ENTIRE car was 3D printed and try to figure which portions were 3D printed.

They’re so wrong. And 3D printing is so right.

Via Bangshift