After our green filament post earlier discussion of 3D printing greenness continued and resulted in a pointer to a document posted by the American Chemical Society that investigates the electricity consumed and CO2 emitted by different manufacturing materials. What exactly did they examine?

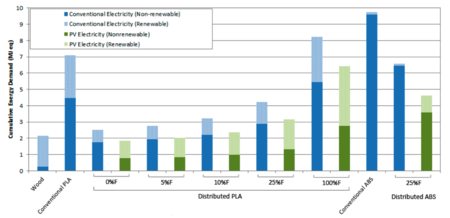

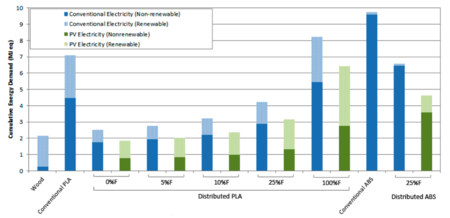

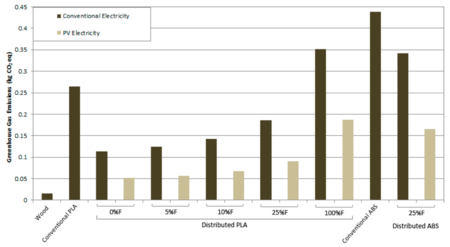

The embodied energy and emissions from conventional large-scale production in low-labor cost countries and shipping are compared to experimental measurements on a RepRap with and without solar photovoltaic (PV) power fabricating products with acrylonitrile butadiene styrene (ABS) and polylactic acid (PLA).

In other words, they’re checking the costs of Asian manufacturing and shipping versus producing onsite using 3D print technology. And by costs, we mean electricity consumption and greenhouse gas emissions.

What did they find? On the chart at the top (click for larger view) you’ll see their analysis of electrical consumption. The chart immediately above is similar, but measures CO2 emissions.

You’ll see that:

- ABS is generally environmentally worse than PLA

- PLA can approach wood’s electrical cost if thin fill is used

- Photovoltaic electricity can substantially decrease CO2 emissions

The study is informative, but speaks only in general terms. The researchers performed the study by 3D printing several simple shapes and measuring the results and effects. Reality is likely a lot more complex, as manufacturing decisions are made on many other factors in addition to electricity and emissions.

We think this type of analysis suggests the winds are beginning the change for manufacturing. Expect more to come.

Via ACS (PDF) (Hat tip to Inkonova)