Associate Professor of Industrial and Systems Engineering Yong Chen of the University of Southern California has been experimenting with different mechanical arrangements for 3D extrusion printing.

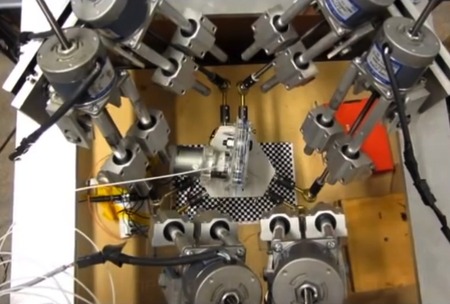

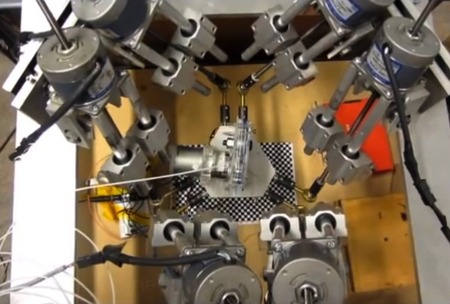

Readers are likely familiar with the standard cartesian XYZ 3 axis configuration typically found in inexpensive personal 3D printers. You may also be familiar with the “delta” concept, in which three vertical axes can maneuver an extruder around the print bed. But Chen has gone further with the introduction of a six axis 3D printer.

The six axes operate similar to a delta unit, but offer the ability to tilt the extruder. This means, for example, this device can print on a slanted surface as the image above shows.

Even more amazing is its ability to print on a curved surface, as seen here in the example of a print pasted onto a glass bottle.

While these are indeed advanced functions, we’re not sure how often they’d actually be used. Worse, the six axes require more components and that means more cost. However, research must be done to explore alternatives and that has certainly been done here.

Via YouTube