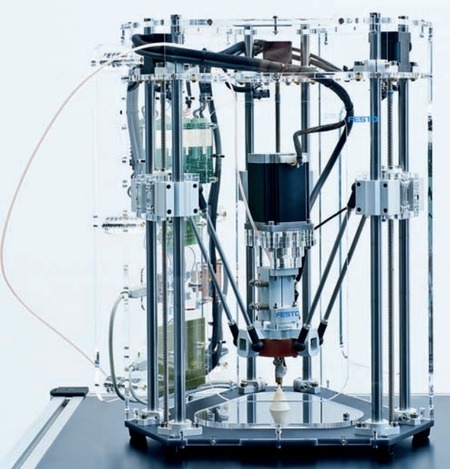

We ran across an experimental 3D printer developed years ago by Festo, a German industrial conglomerate. The iFab was designed in 2009 by Festo’s Bionic Learning Network, but seems to have never been marketed publicly.

The iFab is an early example of a non-cartesian 3D printer. “Cartesian” 3D printers use standard “X-Y-Z” movements as their method of transporting the extruder during printing. Non-cartesian 3D printers use alternative means and there are many different designs. One such non-cartesian design is the Delta Robot approach, also used by the DeltaMaker and Kossel Clear 3D printers – albeit years after the iFab’s creation.

The Delta approach offers several advantages, including higher accuracy, ability to scale easily and the moving apparatus can be less weighty. Plus it’s totally fascinating to watch during printing.

The iFab video shows a very well-constructed and attractively styled machine that although slow by today’s standards, clearly would have been one of the industry leaders at the time of its creation. It even included exchangeable extruder modules, with the intention of 3D printing food. They say:

Festo intends to use the iFab project to come closer to realising the future vision of personalised production. The success story of the PC is to be repeated with the iFab for individualised fabrication. Festo intends to play a leading role in attaining this technological leap brimming with unimagined opportunities.

Unfortunately, this did not come to pass. While Festo’s corporate infrastructure permitted engineers the time and materials to create this amazing machine, their early lead was overtaken by more nimble startup companies such as MakerBot and BFB.

Via Festo