Researchers at the Tokyo Institute of Technology and C-MET have developed a specialized resin that is suitable for 3D printing electronics at a microscopic scale.

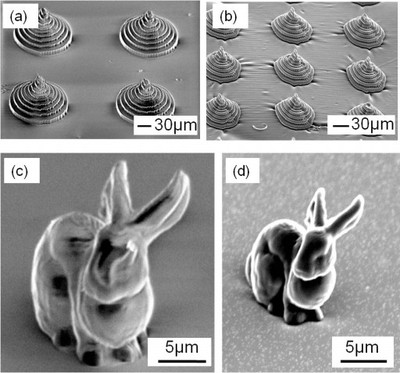

The goal was to develop a material usable to create micro-sized electrodes. Apparently a “carbonization” stage is required to create electrical conductivity, but current materials could not withstand that process. Deformation during carbonization defeated the builds.

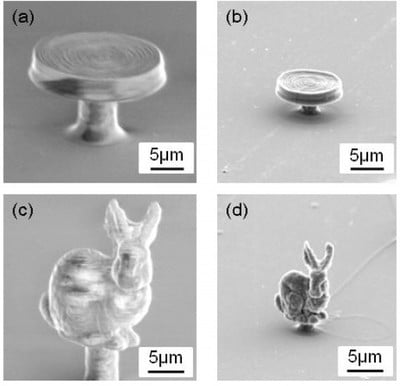

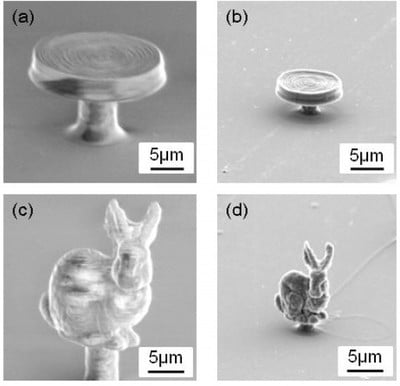

The new material is able to withstand carbonization and is also available as a liquid resin. This means conventional resin-based 3D printing approaches could print this material. The researchers tested this with an ultraviolet light curable print and a laser curing process. Both appear to work.

This development could open up many new applications for 3D printing. For example, the researchers suggest building very small coils that could be used for heating, or electrical interfaces to the human brain.