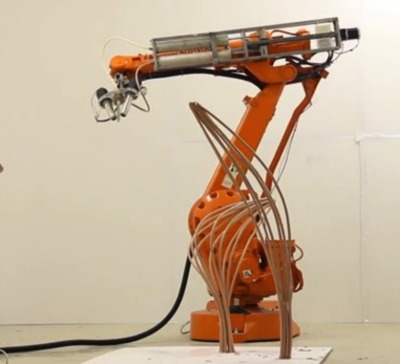

Virtually all 3D printers today use a layered approach, where the object being printed is “sliced” into layers, or horizontal planes, which are printed using whichever technology is at hand. But a project by researchers from the Institute for Advanced Architecture of Catalonia and Joris Laarman Lab proves there is another way.

The Mataerial device is basically a conventional robot arm equipped with a very special extruder. Instead of melting plastic and hoping it cools quickly when extruded, Mataerial uses a polymer that instantly solidifies by chemical reaction when extruded. This means they can do “impossible” feats, such as extruding horizontally in mid-air without any support material.

As you can see in this video, Mataerial can indeed print in this way. But we foresee some interesting challenges if this method becomes popular.

First, the traditional layered 3D printing approach vastly simplifies the process of building, because you don’t need to worry about bumping into any previously printed material – it’s always all below the current print layer. Not so with Mataerial’s approach; complex software must somehow guide the robot arm carefully around all previously printed material, lest disaster strike.

Secondly, the video shows extrusions of independent strands only. There doesn’t seem to be extrusions on top of extrusions. We’re not sure if this is a limitation of the extruded material or simply the designs chosen to print. If the former, the printing of more “solid” objects could be tricky. We imagine software would have to be developed to carefully build items from the inside to the outside. Perhaps the complexity of that software prevented the team from building that kind of object in the demonstration?