Producing high-quality prints is a complicated business, it turns out. There must be synchronization between the slicing software, the printer hardware and the plastic filament used. 3D printer manufacturers who supply these things must do extensive testing to ensure their product works correctly – and homebuilt 3D printers must undergo similar calibration.

MakerBot does exactly this for their Replicator 3D printer and associated MakerWare software. They’ve published a peek at their testing procedure, which attempts to ensure each release of MakerWare can handle all geometric situations that might be encountered.

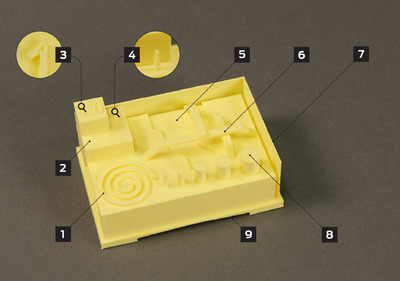

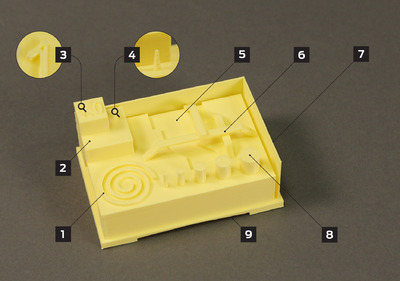

They’ve produced a test object for this purpose, which enables testing of:

- Internal spurs

- Dimensional accuracy

- Tall thin towers

- Flat surfaces

- Bridging

- External spurs

- Curve dimensions

If you’d like to test your 3D printer’s capability, you might want to try printing their test object by downloading it from Thingiverse. It’s called the “MakerBot Slicing Engine Torture Test”.

http://www.thingiverse.com/thing:64549

If you’ve ever had to do this type of calibration yourself, you’ll appreciate MakerBot for doing this work to improve print quality release after release.

Via MakerBot