We spoke with Dr. Martin Schwentenwein, who’s associated with Lithoz, a new Austrian company based in Vienna that has just developed a brand new ceramic 3D printer, the CeraFab 7500.

This fridge-sized device is specifically designed to 3D print ceramic materials. Lithoz’s LCM technology prints Objects by repeatedly photo-curing whole layers within a slurry of ceramic particles and a binder. After printing the object is then fired in a furnace to burn out the binder and fuse the ceramic particles into its final form.

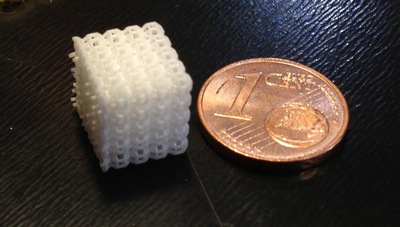

The results are stunningly beautiful; they require no finishing beyond the final firing to form their smooth, layer-less texture. Evidently the accuracy is in the 0.1mm range, but it seemed even finer when examining some sample prints. Check out the detail on this item. What you can’t see is the strength of this material. You’d find it very difficult or even impossible to crush this cube using your fingers alone.

The device has just been released so we are not certain of its final price, but we suspect it will be in the €200,000 range when it hits the reseller market.

Via Lithoz