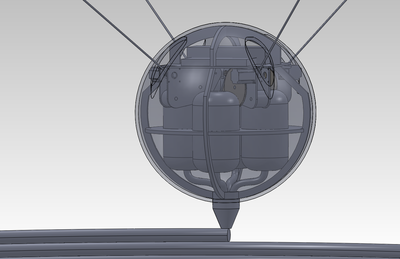

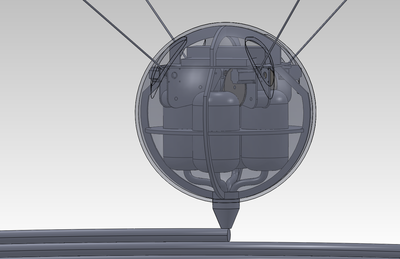

Ben Peters of the MIT Media Lab is working on something called the “Spiderbot”, which is:

A lightweight self-contained cable suspended robot, moving similar to a SkyCam in stadiums, for 3d printing structures by attaching to high points in surrounding environments (trees, buildings, etc.)

We have seen several approaches for 3D printing large structures previously, but all involved massive beams and rods for moving a massive print head to and fro in building sized volumes. Obviously there is a cost to all that hardware, but the Spiderbot attempts to avoid that problem entirely.

Rather than having its own frame, the Spiderbot is hung from nearby tall points by wires. By pulling and releasing these guide wires, the Spiderbot “nucleus” can quickly move about – and extrude material as it travels. The approach was inspired by those zippy action cams at major sports events that whip around to get you choice shots. If they are easy enough to install and take down for a sports event, why couldn’t the same approach be used for 3D printing?

One issue is weight. You couldn’t support a concrete 3D print head in this way, as wires would likely be insufficient to prevent a catastrophic head crash. However, the Spiderbot concept involves extruding very light material – such as Urethane. It’s a liquid plastic that foams upon extrusion and then solidifies within 30 seconds.

That leads to the second issue: strength. Would you want to live in a house made of Urethane? We don’t either, as the first burst of wind would blow it away. Spiderbot solves this issue by 3D printing not walls but a mold into which regular concrete may be poured. Then imagine you’re living in a concrete house coated with insulating Urethane. Nice!

There are no doubt many more issues to solve, not the least of which will be the accuracy of a wire-suspended extruder, particularly in windy conditions. But we’re certain they’re working on it.

Via Bengineering